Skq61100 Large Swing Horizontal CNC Lathe Machine

CKD6163 Series Horizontal CNC Lathe Machine is a kind of high efficiency CNC lathe with reasonable structure, excellent manufacture, advanced configuration and beautiful shape.

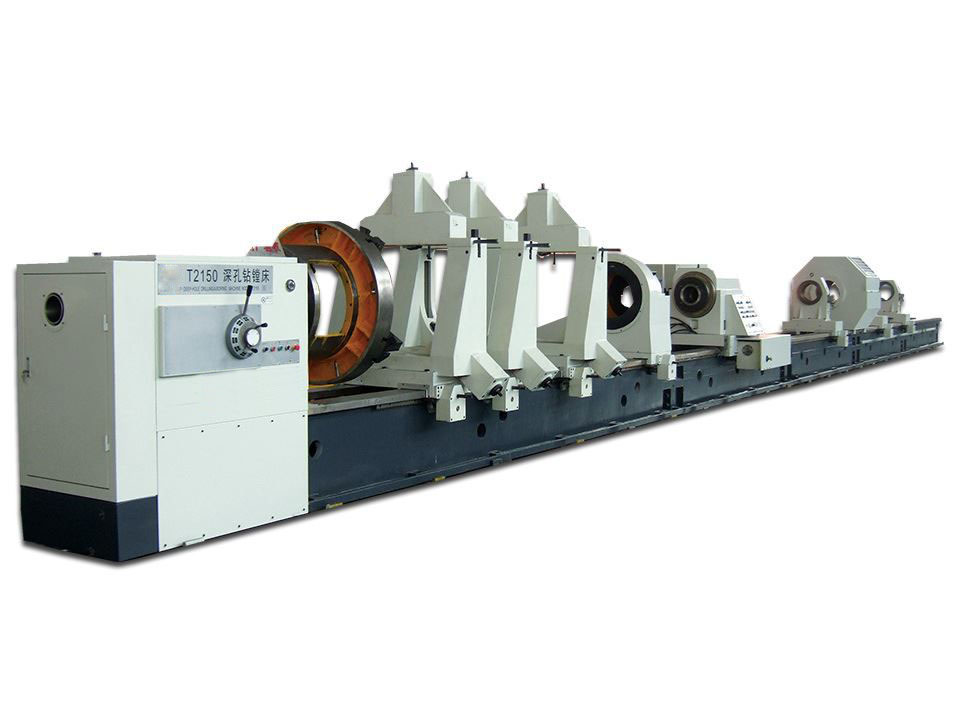

For many years, we have been aiming to create excellent quality and high reliability Double Column Vertical Lathe Machine 40tons, CNC Deep Hole Gun Drilling Machine, CNC Slant Bed Lathe, and regard the needs of users as the basis of our research and development. We have a dream, the pursuit of excellence, always grateful, and willing to give. Our company has independent research and development, production and manufacturing teams and research and development outstanding talents, in line with the guiding ideology of serving users and serving customers, we will work hand in hand with enterprises in the industry.

CKD6163 Series Horizontal CNC Lathe Machine is a kind of high efficiency CNC lathe with reasonable structure, excellent manufacture, advanced configuration and beautiful shape. Through the automatic control of the numerical control system, the machine tool can process all kinds of inner holes, outer circles, conical surfaces, arc surfaces and threads within the processing range, especially suitable for rough and fine machining of small and medium batches of shaft and disk parts. It has the advantages of high automation, simple programming and high precision. Compared with the same type of domestic machine tools, it has the following characteristics.

Specification

General parameter | |

Maximum swing diameter over bed | φ 630mm |

| Maximum swing diameter over sliding plate | φ 390mm |

Maximum center distance | 2000 mm |

| Maximum turning diameter (end face) | φ 560mm |

| Headstock | |

| Spindle through hole diameter | φ 120 mm |

| Spindle taper | 1:20 |

| Spindle head specification | D11 |

| Spindle speed | 12-1000 r/ min (18 stages of speed change) |

| Cutting system | |

| X-axis fast moving speed | 3000 mm / min |

| Z-axis fast moving speed | 6000 mm / min |

| Longitudinal minimum resolution | 0.01 mm |

| Transverse minimum resolution | 0.005 mm |

| Tool post | |

| Distance from spindle center to tool mounting plane | 32 mm |

| Section size of tool | 32 × 32mm |

| Tool form | 4-position electric tool holder |

| Tail stock | |

Diameter of tailstock spindle | 100mm |

| Taper of tailstock spindle | Morse taper No.5 |

Maximum stroke of tailstock spindle | 250 mm |

Power part | |

| Main motor model | Y132M-4 |

| Main motor power | 7.5kw |

| Cooling oil pump | |

| Oil pump model | JCB-22 |

| Oil pump power | 0.125 kw |

| Oil pump flow | 22 L / min |

Machine Tool Accuracy | |

| Precision of finish turning outer circle | Roundness 0.005 Ra≤1.6 um |

Cylindricity is 0.03 on 300 measurement length | |

| Flatness of finish turning end face | 0.025 on 300 dia |

| Standard configuration | |

| With manual three-jaw chuck φ380mm | 1set |

| Steady rest 20-200m | 1set |

| Follow rest 20-110mm | 1set |

| Center sleeve | 1set |

| Morse 5# center | 1set |

| Oil gun | 2set |

| Tools | 1pcs |

| Foundation screws | 1set |

Document with Machine for One Machine Tool

Content | Document | Number | Note |

1 | Operational manuals | 1 | Mechanical and electrical |

2 | Acceptance of certificate | 1 |

|

3 | Packing list | 1 |

Through independent innovation, we have made every effort to develop new Skq61100 Large Swing Horizontal CNC Lathe Machine, giving new connotation and vitality to the traditional products. We will give full play to our own advantages and aim to grow into an enterprise with "well-managed, exquisite business, excellent assets and strong profitability". We provide you with high-quality products and services with excellent technology and equipment, advanced design concept, professional production process, customer-oriented service consciousness and competitive cost advantage.

Welcome to send your message to us