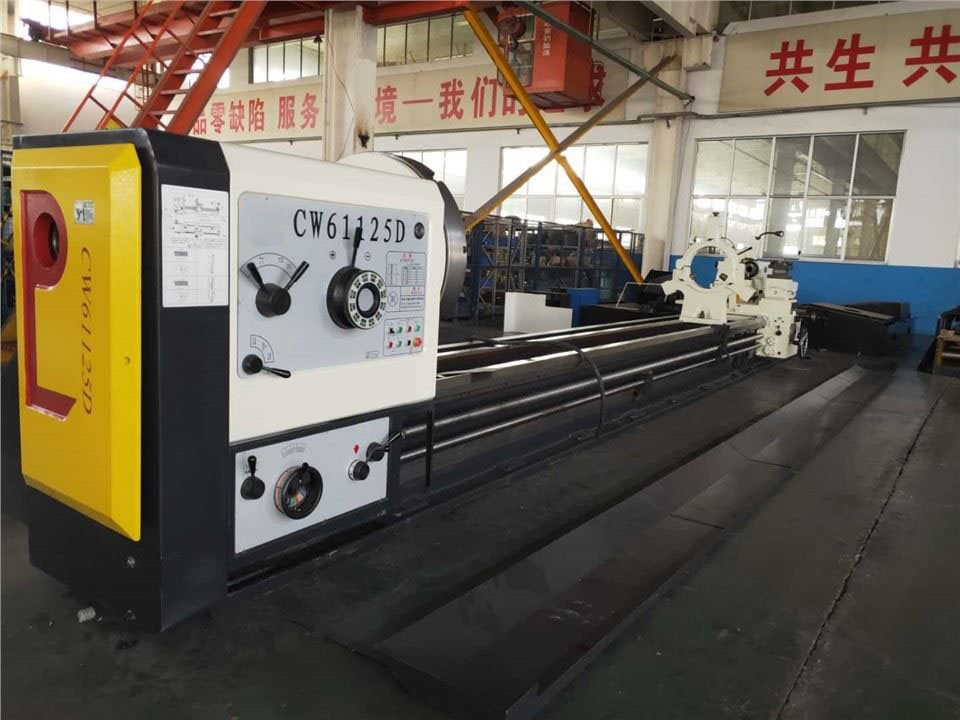

Automatic Slant Bed Metal Cutting Linear Rail High Speed High Precision CNC Lathe with Robot Production Line

CKD-H Series CNC High Precision Lathe 20Tons load is a CNC lathe developed by our company, which is a large-size CNC lathe product. The machine tool has the characteristics of high efficiency, high stability, high precision, high versatility and high rigidity.

To fulfill the customers' over-expected satisfaction, we have now our strong crew to provide our greatest general assistance which incorporates promoting, gross sales, planning, creation, top quality controlling, packing, warehousing and logistics for Heavy Duty CNC Lathe Machine, T2136G Deep Hole Drilling And Boring Machine, CK6150S CNC Slant Bed Lathe. We constantly optimize the benefits and performance appraisal system and improve competitive salary and wages. On the basis of every employee striving to be the first and not being willing to lag behind, we maintain the company's continuous good business situation and promote the rapid development of the enterprise. We always advocate the establishment of a good moral style, care and love of public welfare, and actively carry out various types of charitable donations and social assistance activities. Our company is committed to building a brand, excellent quality, reputation for the "three" standard enterprise.

CKD-H Series CNC High Precision Lathe 20Tons load is a CNC lathe developed by our company, which is a large-size CNC lathe product. The machine tool has the characteristics of high efficiency, high stability, high precision, high versatility and high rigidity. The bed adopts flat-V guide rail, after intermediate frequency quenching and precision grinding, it has high rigidity and can withstand heavy load precision cutting. The machine tool is equipped with KND2000T,SIEMENS or FANUC control system and servo feed motor, with perfect functions and reliable performance. The domestic famous brand ball screw is selected, with high precision and high efficiency

Specification | Technical data | ||||||

CKD61125H | CKD61140H | CKD61160H | CKD61180H | CKD61200H | |||

Capacity | Max.swing diameter over bed | 1290 | 1440 | 1640 | 1840 | 2040 | |

Max.swing dia.over carriage | 900 | 1050 | 1250 | 1450 | 1600 | ||

Width of bed | 1100mm | ||||||

Max.workpiece length | 1000 2000 3000 4000 5000 6000-16000(mm) | ||||||

Weight of workpiece between two centers | 20t | ||||||

Spindle | Range of spindle speed | 3.15-315r/min | |||||

Spindle bore diameter | 130mm | 130mm | |||||

Front taper of the spindle internal hole | metric140# | ||||||

Feeds | Max. stroke on X-axis | 650 | 750 | 750 | 850 | 850 | |

Max. stroke on Z-axis | 800, 1800, 2800, 3800, 4800-15800 (mm) | ||||||

Rapid speed X-axis | 4m/min | ||||||

Rapid speed Z-axis | 4m/min | ||||||

CNC System | KND2000T(Or Fanuc, Siemens ) | ||||||

Tool Turret | Tool post | 4 | |||||

Size of tool section | 55×55mm | ||||||

Tailstock | Diameter of tailstock sleeve | Φ280 | |||||

Travel of tailstock sleeve | 300mm | ||||||

Taper of tailstock sleeve | 1:7 | ||||||

Tail stock motorized speed | 1m/min | ||||||

Others | Machine Length | 4527, 5527, 6527, 7527, 8527-19527 (mm) | |||||

Machine width | 2840mm | ||||||

Main motor power | 30kw | ||||||

chuck | 1250mm | 1400mm | 1600mm | ||||

StandardAccessories

1. 1:7 center 1 pc

2. tool with machine 1set

3. foundation screw 1set

4. nut washer 1set

5. (steady rest ф120-480mm 1set for 25H/1,40LH/1,60H/1)

(steady rest ф400-700mm 1set for 80H/1,200H/1)

We hope to obtain the greatest profit with the smallest investment, and help customers increase production efficiency and improve quality of Automatic Slant Bed Metal Cutting Linear Rail High Speed High Precision CNC Lathe with Robot Production Line. We continue to promote technological progress and innovation, and strive to develop the industry and realize the sustainable operation of the company. Our development will never stand still, and we will strive to achieve scientific development and write a new brilliant chapter with new performance worthy of the nation and the times!

Welcome to send your message to us