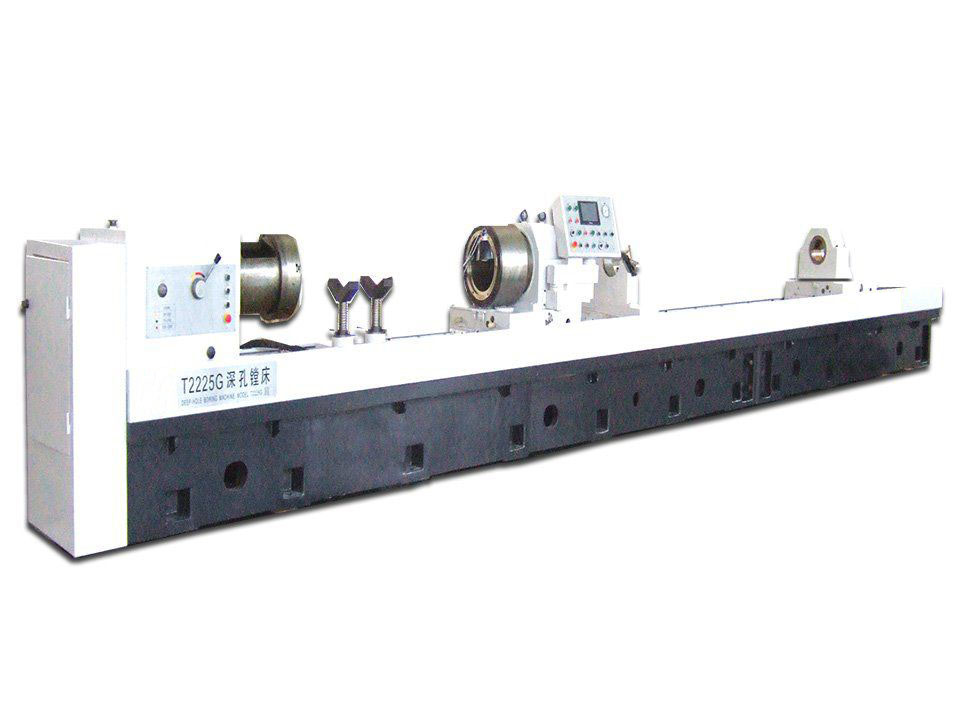

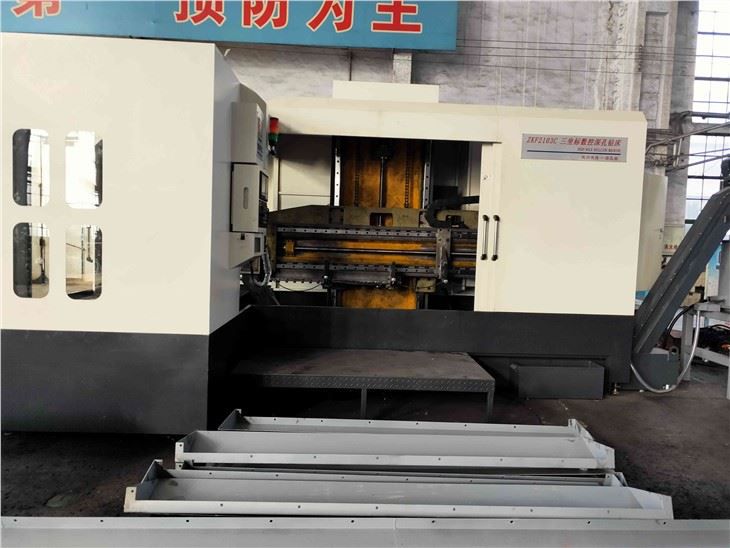

Zkb2102 Three Coordination CNC Deep Hole Gundrilling Machine, Deep Hole Drilling, , Hole ...

The usage of the machine,the machine is special equipment for machining deep cylindrical hole of workpieces.It suitable for boring the cylindrical workpiece.When boring the hole,the oil is supply from the guide carriage,and take the chips from the cutting area to the equipment of chip conveying on the headstock.

Our company adopts a unique production process and production technology. Our CNC Heavy Duty Lathe 25Tons Load, T2180 Deep Hole Drilling And Boring Machine, CNC High Precision Lathe have excellent and stable performance, complete models and exquisite packaging. We attach importance to environmental protection and the rational use of natural resources, and fulfill our due obligations to society. We not only provide customers with high-quality equipment and services, but also provide comprehensive technical support. The company insists on taking technological innovation and leapfrog development as the driving force, and has developed a variety of products by itself.

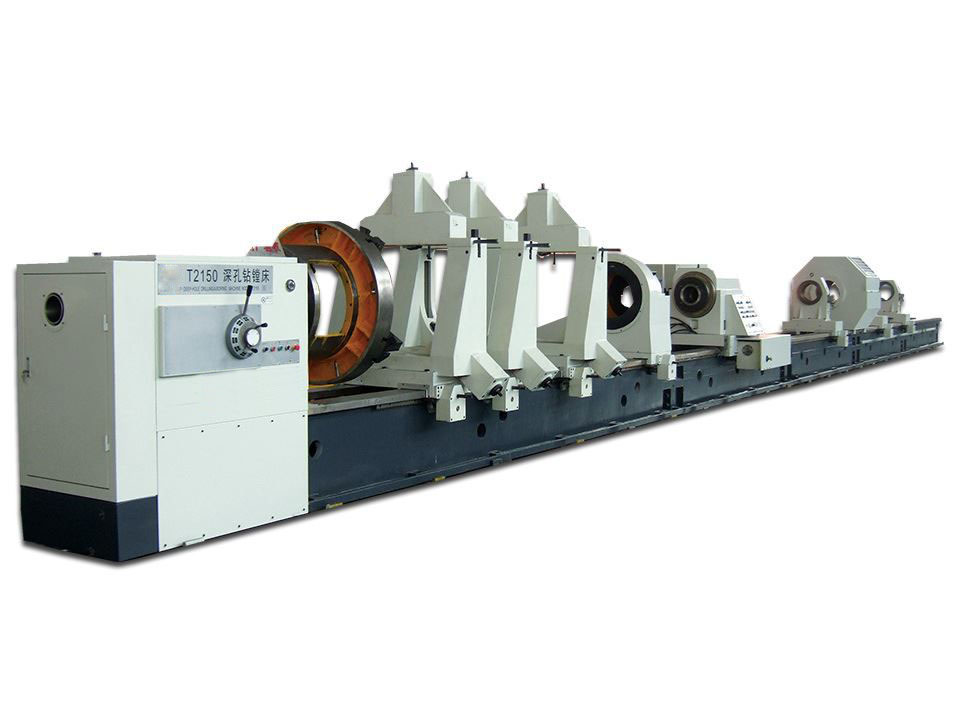

T21100 Deep Hole Drilling and Boring Machine:

The usage of the machine,the machine is special equipment for machining deep cylindrical hole of workpieces.It suitable for boring the cylindrical workpiece.When boring the hole,the oil is supply from the guide carriage,and take the chips from the cutting area to the equipment of chip conveying on the headstock. The drilling method is the internal removal chip(BTA method) when drill.The oil is supply from the guide carriage,and take the chips from the cutting area to the equipment of chip conveying in the back of machine.

The machine is controlled by PLC, the reciprocating movements of guide carriage and feeding carriage are controlled by the servo motor.The drive is made by the racks in the two to ensure long movement feeding transmission accuracy and rigidity requirements. The protection on the two sides of the bed body and the use of the ground oil tank structure improve machine tool environment. The machine can be equipped with two automatic or manual expansion efficient tool,it greatly improves the machining efficiency.

| model item | T21100 |

| the range of drilling diameter | φ60mm~φ120mm |

| the range of boring diameter | φ1000mm |

| the range of boring depth | 1500~18000mm |

| the height of center | 1050mm |

| the range of chuck clamp. diameter | φ270~φ1500mm |

| the range of steady rest clamp. diameter | φ270~φ1000mm |

| the range of roller support clamp. diameter | φ800~φ1600mm |

| range and kinds of spindle speed | 3~120r/min three grade stepless |

| range and kinds of drilling box speed | 32~400r/min 12 kinds |

| the diameter of spindle front bearing | φ280mm |

| the diameter of spindle bore | φ120mm |

| the taper of spindle nose | METRIC 140# |

| the diameter of chucks | φ1650mm |

| the rapid speed | 2000mm/min |

| the feeding rapid speed | 0.5~250mm/min (stepless) |

| the main motor power | N=75kW/132kw |

| the power of drilling box motor | N=45kW |

| the feeding motor | N=7.5kW/11kw, AC servo motor |

| the max. weight of workpiece | 40t/63t/80t |

We provide fantastic energy in top quality and advancement, merchandising, gross sales and marketing and operation for Zkb2102 Three Coordination CNC Deep Hole Gundrilling Machine, Deep Hole Drilling, , Hole .... Our social responsibility concept is finally implemented in the practice of scientific and technological innovation, energy saving and environmental protection, and employee care. Our company's technical support and research and development capabilities in the same industry is first-class.

Welcome to send your message to us