Vertical Cylinder Grinding Honing Machine 3MB9817

The usage of the machine,the machine is special equipment for machining deep cylindrical hole of workpieces.It suitable for boring the cylindrical workpiece.When boring the hole,the oil is supply from the guide carriage,and take the chips from the cutting area to the equipment of chip conveying on the headstock.

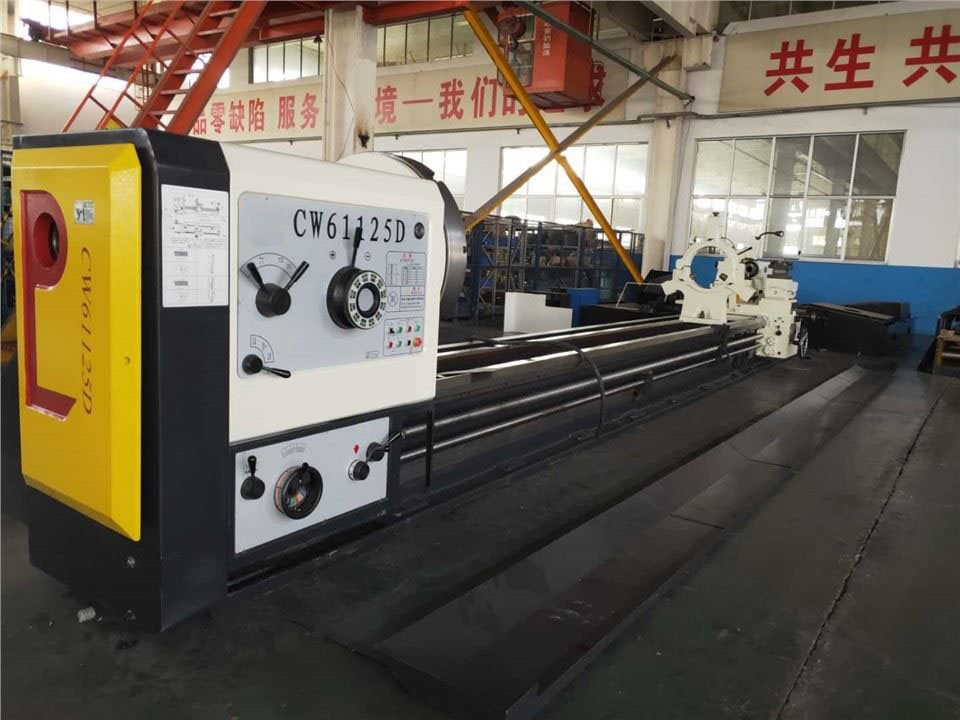

We believe that we will create a better relationship with you by virtue of our high quality CW-H Series Heavy Duty Horizontal Lathe Machine 20Tons Load, T2125G Deep Hole Drilling And Boring Machine, Deep Hole Boring Cutting Tool, reasonable prices, considerate and fast service and good communication and cooperation ability. Our commitment to sustainability is one of the main drivers of our ongoing search for new technologies. We achieve high customer satisfaction, increase customer stickiness and extend asset life cycle. We believe that the harmony within a company is the unity of a strong company, employee happiness, customer satisfaction, and social benefit. We think this sets us apart from the competition and makes prospects choose and trust us.

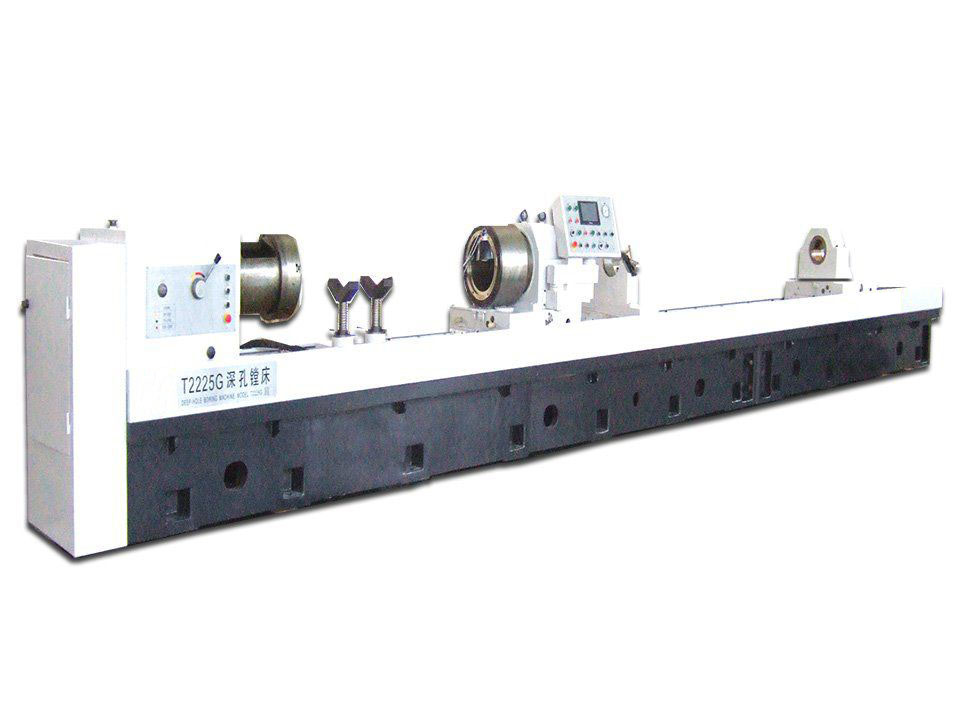

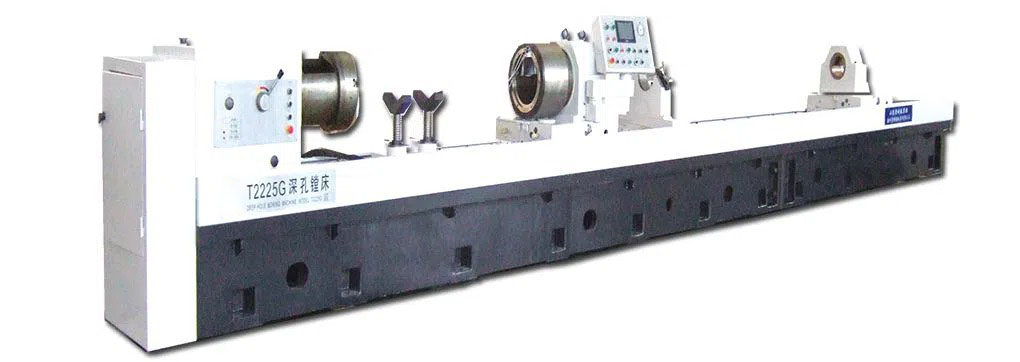

The usage of the machine,the machine is special equipment for machining deep cylindrical hole of workpieces.It suitable for boring the cylindrical workpiece.When boring the hole,the oil is supply from the guide carriage,and take the chips from the cutting area to the equipment of chip conveying on the headstock.

The machine is controlled by PLC, the reciprocating movements of guide carriage and feeding carriage are controlled by the servo motor.The drive is made by the racks in the two to ensure long movement feeding transmission accuracy and rigidity requirements. The protection on the two sides of the bed body and the use of the ground oil tank structure improve machine tool environment. The machine can be equipped with two automatic or manual expansion efficient tool,it greatly improves the machining efficiency.

The machine is a kind of deep hole boring machine with easy to operate and control, high efficiency and environmental friendly.

Item | T2225G, T2225G /1 |

the range of boring diameter | Φ40~250mm |

the height of center | 400mm |

the range of boring depth | 1000-10000mm |

the diameter of chucks | φ400mm |

workpiece clamped dia. Range of | φ50~φ400mm |

range and kinds of spindle speed | 40~500r/min 3 grades 12 kinds |

the power of main motor | N=30kW |

range of feeding speed | 5~2000mm/min ( stepless) |

feeding motor | N=4.5kW servo motor |

guide carriage motor | N=6.7kW servo motor |

cool pump motor power | 5.5KW; |

rated pressure of cooling system | 2.5MPa |

the flow of cooling system | 100, 200, 300, 400L/min; |

We have optimized our own business operation system and continuously introduced more applicable Vertical Cylinder Grinding Honing Machine 3MB9817 and quality services to the society. The company conducts training every year to help employees improve themselves and enrich corporate cultural activities. From understanding the needs of customers to the efficient operation of all links to the final delivery of services, we always take customer satisfaction as the highest goal, continuously and steadily provide products and services that meet or exceed expectations through continuous improvement and development of ourselves.

Welcome to send your message to us