vertical boring and honing machine for motorcycle cylinder TM807A

HMS25 HMS35 HMS50 Deep Hole Honing Machine is specially used for finishing the inner hole surface of various hydraulic cylinders, cylinders and other cylindrical parts. After machining, the aperture accuracy of the parts reaches above it7, and the surface roughness reaches ra0.2-0.4 μ m.

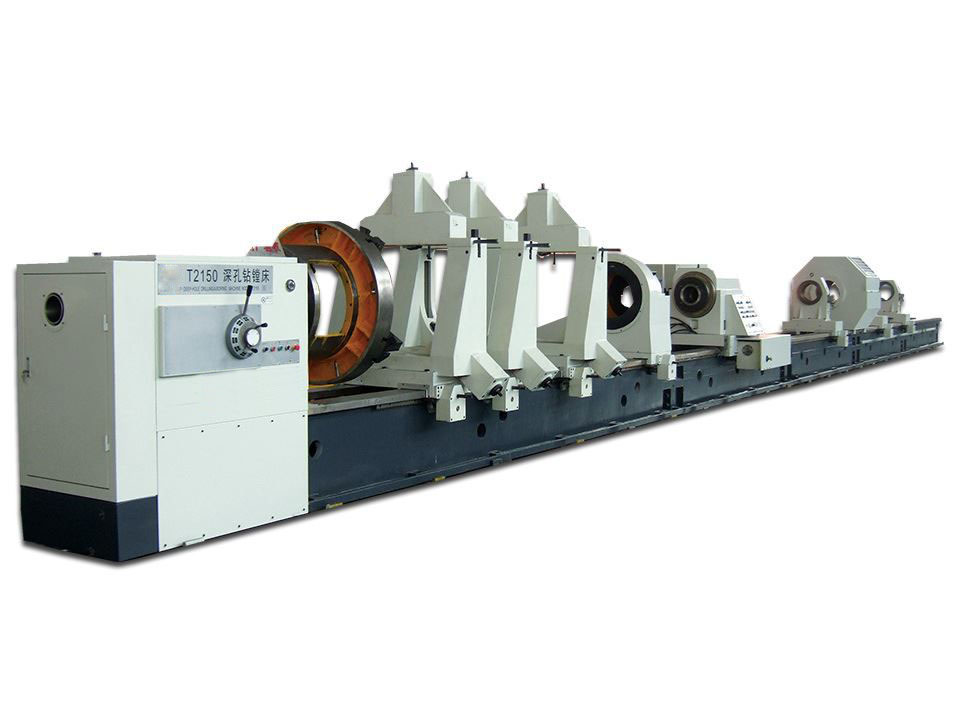

With our rich experience and considerate services, we have been recognized as a reliable supplier for T2125G Deep Hole Drilling And Boring Machine, CKD6163 Series Horizontal CNC Lathe Machine, Heavy Duty Lathe Machine. We should pursue a new realm and path of co-construction, co-creation, co-existence, win-win and co-prosperity. We have established long-term strategic partnerships with many companies, and we are the backbone of the industry and have won the high trust of our partners.

HMS25 HMS35 HMS50 Deep Hole Honing Machine is specially used for finishing the inner hole surface of various hydraulic cylinders, cylinders and other cylindrical parts. After machining, the aperture accuracy of the parts reaches above it7, and the surface roughness reaches ra0.2-0.4 μ m. The machine tool can also carry out local honing to correct the taper and ovality of parts.

The machine tool is equipped with Siemens 808d CNC system, linear rolling guide rail, Beijing CTB AC servo motor, and the grinding rod box adopts variable frequency motor with stepless speed regulation.

The honing process adopts constant pressure control, and the sand bar and workpiece always maintain constant pressure. For general cylindrical deep hole parts, the inner hole needs to be honed after boring; Cold drawn steel pipes with small allowance can be honed directly. Different honing oilstones are selected according to different materials, different physical characteristics and specific processing requirements.

The cooling system adopts three-stage filtration, and the filtration accuracy can reach 30 μ m. The CNC system of machine tool integrates current detection, pressure display, etc.

Technical specifications | HMS25 | HMS35 | HMS50 |

Honing diameter range | Φ20~Φ250 | Φ20~Φ350 | Φ80~Φ500 |

Maximum honing depth | 8000 | 8000 | 8000 |

Diameter range of clamping workpiece | Φ25~Φ350 | Φ20~Φ450 | Φ80~Φ600 |

Spindle speed range | 10~250r/min | 10~250r/min | 30~200r/min |

Reciprocating speed range | 3-20m/min | 3-20m/min | 3-20m/min |

Motor power of grinding rod box | 7.5kW(frequency motor) | 11kW(frequency motor) | 15kW(frequency motor) |

Hydraulic system oil pump flow | 12.5L/min | 12.5L/min | 12.5L/min |

Rated working pressure of hydraulic system | 4MPa | 4MPa | 4MPa |

Cooling pump flow | 50L/min | 100L/min | 150L/min |

Cooling tank volume | 600L | 950L | 950L |

Hydraulic system motor power | 1.1kW | 1.1kW | 1.1kW |

Cooling pump motor power | 2.2kW | 2.2Kw(2 groups) | 2.2kW(2 groups) |

Reciprocating motor power | 5.5kW | 7.5kW | 7.5kW |

We always adhere to the 'integrity, development, heart, win-win' concept, hope to make friends with domestic and foreign customers, to provide you with good vertical boring and honing machine for motorcycle cylinder TM807A, technology and services. We have always insisted on making continuous efforts and striding forward towards a model of the industry. Our products have entered the international market, the company with strong technical force, strict quality management, excellent manufacturing, after-sales service to win the praise of the majority of users.

Welcome to send your message to us