vertical boring and honing machine for motorcycle cylinder TM807A with ce

HMS25 HMS35 HMS50 Deep Hole Honing Machine is specially used for finishing the inner hole surface of various hydraulic cylinders, cylinders and other cylindrical parts. After machining, the aperture accuracy of the parts reaches above it7, and the surface roughness reaches ra0.2-0.4 μ m.

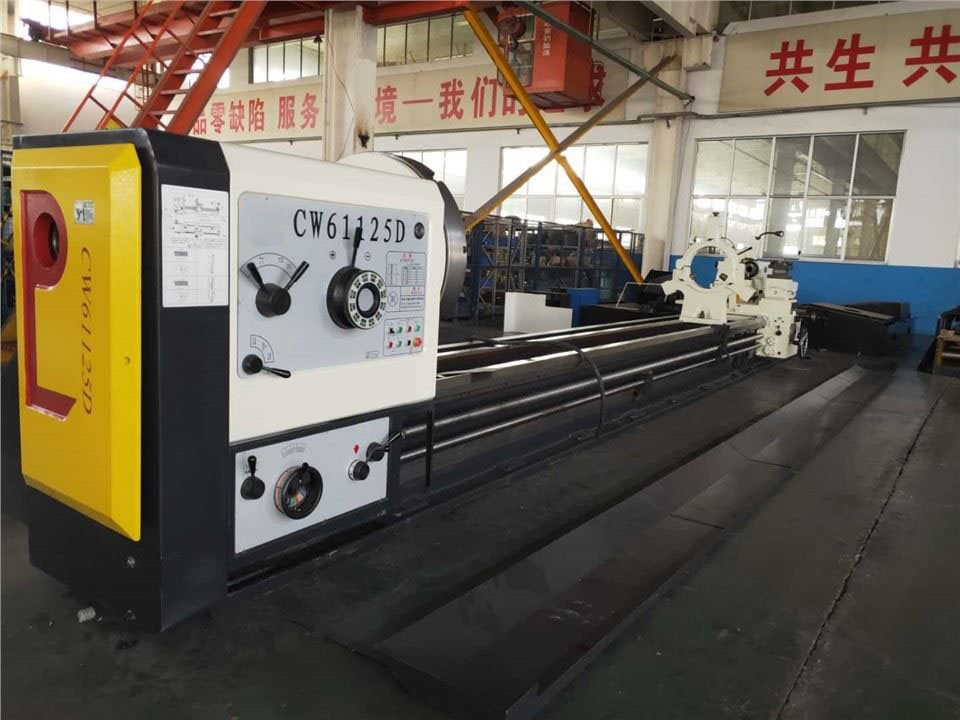

Each of our CKD6163D Series CNC Lathe Machine 3Tons Load, CD6150B Horizontal Conventional Lathe Machine, Heavy Duty CNC Lathe Machine 80Tons Load is very user-friendly and can meet the diversified needs of users at any moment, and bring them a comfortable experience. We are enthusiastic about public welfare, create green space, and dedicate ourselves to social harmony and stability and sustainable development. We always insist on taking technological innovation and management innovation as the driving force, insisting that technological status determines market status and market status determines corporate status.

HMS25 HMS35 HMS50 Deep Hole Honing Machine is specially used for finishing the inner hole surface of various hydraulic cylinders, cylinders and other cylindrical parts. After machining, the aperture accuracy of the parts reaches above it7, and the surface roughness reaches ra0.2-0.4 μ m. The machine tool can also carry out local honing to correct the taper and ovality of parts.

The machine tool is equipped with Siemens 808d CNC system, linear rolling guide rail, Beijing CTB AC servo motor, and the grinding rod box adopts variable frequency motor with stepless speed regulation.

The honing process adopts constant pressure control, and the sand bar and workpiece always maintain constant pressure. For general cylindrical deep hole parts, the inner hole needs to be honed after boring; Cold drawn steel pipes with small allowance can be honed directly. Different honing oilstones are selected according to different materials, different physical characteristics and specific processing requirements.

The cooling system adopts three-stage filtration, and the filtration accuracy can reach 30 μ m. The CNC system of machine tool integrates current detection, pressure display, etc.

Technical specifications | HMS25 | HMS35 | HMS50 |

Honing diameter range | Φ20~Φ250 | Φ20~Φ350 | Φ80~Φ500 |

Maximum honing depth | 8000 | 8000 | 8000 |

Diameter range of clamping workpiece | Φ25~Φ350 | Φ20~Φ450 | Φ80~Φ600 |

Spindle speed range | 10~250r/min | 10~250r/min | 30~200r/min |

Reciprocating speed range | 3-20m/min | 3-20m/min | 3-20m/min |

Motor power of grinding rod box | 7.5kW(frequency motor) | 11kW(frequency motor) | 15kW(frequency motor) |

Hydraulic system oil pump flow | 12.5L/min | 12.5L/min | 12.5L/min |

Rated working pressure of hydraulic system | 4MPa | 4MPa | 4MPa |

Cooling pump flow | 50L/min | 100L/min | 150L/min |

Cooling tank volume | 600L | 950L | 950L |

Hydraulic system motor power | 1.1kW | 1.1kW | 1.1kW |

Cooling pump motor power | 2.2kW | 2.2Kw(2 groups) | 2.2kW(2 groups) |

Reciprocating motor power | 5.5kW | 7.5kW | 7.5kW |

Each of our vertical boring and honing machine for motorcycle cylinder TM807A with ce launched on the market has excellent quality and has won high attention and praise from the industry. The company is willing to further develop friendship and sincere cooperation with old and new friends from all walks of life to create a better tomorrow! We believe that only by insisting on self-criticism can we achieve the common development of customers, companies, teams and individuals.

Welcome to send your message to us