Straight Fluted Tungsten Carbide Gun Drilling Tools

Single axis CNC Deep Hole Gun Drilling Machine is used for processing automobiles, motorcycles, oil pump, nozzle, engineering machinery, mining machinery, military industry and other industries, small and medium-sized deep hole axial workpiece of special equipment.

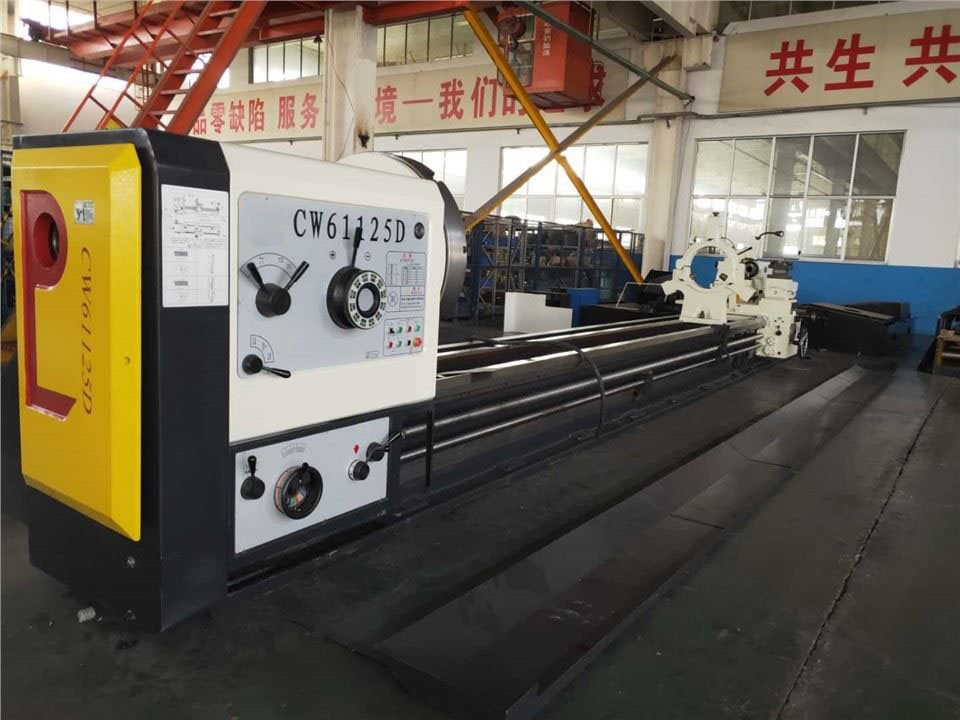

We continuously improve the quality of our work, and customer satisfaction with our CNC Lathe Machine, 2M2150 Deep Hole Honing Machine, Deep Hole Drilling Boring Machine is the highest goal we pursue. Our goal is to provide more convenient services, and our personnel are an important part. Our goal is to become an industry-leading and respected world-class enterprise, to create maximum value for customers, shareholders and employees, and to promote the sustainable development of society. Efficient service, grasp the market changes and needs, strive to provide competitive products and services for global customers, and help customers realize value-added. We follow strict standards and quality inspection methods to ensure product quality and provide good sales service.

Single axis CNC Deep Hole Gun Drilling Machine is used for processing automobiles, motorcycles, oil pump, nozzle, engineering machinery, mining machinery, military industry and other industries, small and medium-sized deep hole axial workpiece of special equipment.

The machine tool equip the headstock, so the workpiece rotate and cutting tool rotate and feed at the same time, and the accuracy is very high.

Machine features

● Bed body and the box body is made of high quality cast iron casting, with good rigidity and stability.

● It doesn't need to return cutting tool in the process of drilling deep hole.

● It adopts CNC control system, a high degree of automation.

● Feed movement is driven by AC servo motor, and is driven by ball screw pair, and it is stepless speed regulation.

● It adopts sliding guide rail, moving parts bottom with special material, low speed running smoothly, without crawling.

● The drilling bar box is stepless speed regulation.

● The bearing of spindle and guideway adopt automatic intermittent lubrication, etc.

● High pressure cooling system adopts that frequency conversion motor drive gear pump, and the immersion cooler can control the oil temperature.

● It adopts automatic chip removal machine.

● It adopts all closed protective cover, and it is convenient to observe and good appearance.

● With multiple automatic monitoring device.

Optional machining method

A. Standard configuration: Workpiece rotate, cutting tool rotate and feed with gun drilling method.

B. Optional method, the workpiece fixed, the cutting tool rotating and feed with gun drilling method.

Standard configuration

Standard KND or GSK980T numerical control system, headstock, flat screen filter, hand pulse control box, drill pipe support, automatic chip removal machine, all protective cover, centralized lubricating oil station, cooling system, warning lights, adjusting tools, working light, tool pad iron, oil temperature controller, hydraulic system, etc.

Optional configuration

Gun drill tools, auxiliary equipment, cutting oil, knife grinder, grinding device, jilt oil machine, drum filter machine, magnetic chip removal machine, electric box air conditioner, Siemens numerical control system, FANUC CNC system, hydraulic tailstock, clamp.

Main technology specification list

| ZK21 A standard parameter | |||

| Technology specification | ZK2102A | ZK2103A | ZK2104A |

| Spindle head number | 1 | 1 | 1 |

| distance between spindles(mm) | - | ||

| drilling hole diameter range(mm) | 3-20 | 8-30 | 10-40 |

| max drilling depth((mm)) | 500/1000/1500/2000/2500/3000 | 450/950/1450/1950/2450/2950 | 450/950/1450/1950/2450/2950 |

| Drilling bar box spindle rotate speed(stepless) r/min | 800-7000 | 600-6000 | 100-3000 |

| Drilling bar box spindle driver motor power | 4kW | 5.5kW | 7.5kW |

|

Headstock spindle speed(fixed value) |

380 r/min | 380 r/min | 380 r/min |

| Headstock spindle motor power | 1.5 kW | 1.5 kW | 5.5 kW |

| Cutting tool feed speed range (stepless) (mm)/min | 5-500 | 5-500 | 5-500 |

| Cutting tool Feed carriage rapid moving speed (mm)/min | 3 | 3 | 3 |

| Cutting tool Feed motor torque Nm | 7.7 | 10 | 10 |

| Coolant system pressure rangeMPa | 1-10 | 1-10 | 1-6 |

| Coolant system flow rangeL/min | 6-100 | 6-100 | 6-150 |

| Machine tool total power (about) | 20 kW | 22kW | 38 kW |

| Overall dimension (L×W×H) | 4050/5050×4050×2050 | 4050/5050×4050×2050 | 4250/250×4450×2050 |

| Total weight (about) | 6t/7t | 6t/7t | 7t/8t |

The accuracy of drilling hole

Accuracy of drilling hole: IT7-IT10 (good condition IT7-IT8; general IT9-IT10) ;

Roughness: Ra 0.4-3.2μm

Deviate of center axis:

A: 0.25mm/500mm (workpiece roate, length :diameter 100: 1, uniform material, suitable feed speed)

B: 0.5mm/1000mm (workpiece roate, length :diameter 100: 1, uniform material, suitable feed speed)

C: 0.5mm/500mm (workpiece not rotate, length :diameter 100: 1, uniform material, suitable feed speed)

D: 1mm/1000mm (workpiece not rotate, length :diameter 100: 1, uniform material, suitable feed speed)

Cutting tool life

Continuous cutting length 12-20m(not include special material)

And cutting tool can use 50times by The cutting tool resharpening , so the total length of cuttting can be more than 600m, good condition is more longer.

We focus on Straight Fluted Tungsten Carbide Gun Drilling Tools production for many years, we also provide personalized customization. Our products have beautiful appearance, various colors and can be customized. We rationalize the allocation of environmental management resources and implement the principle of pollution prevention in the development and production of our products. Our company can provide customers with various quality specifications according to different requirements of customers and maintain long-term interactive relationship with them.

Welcome to send your message to us