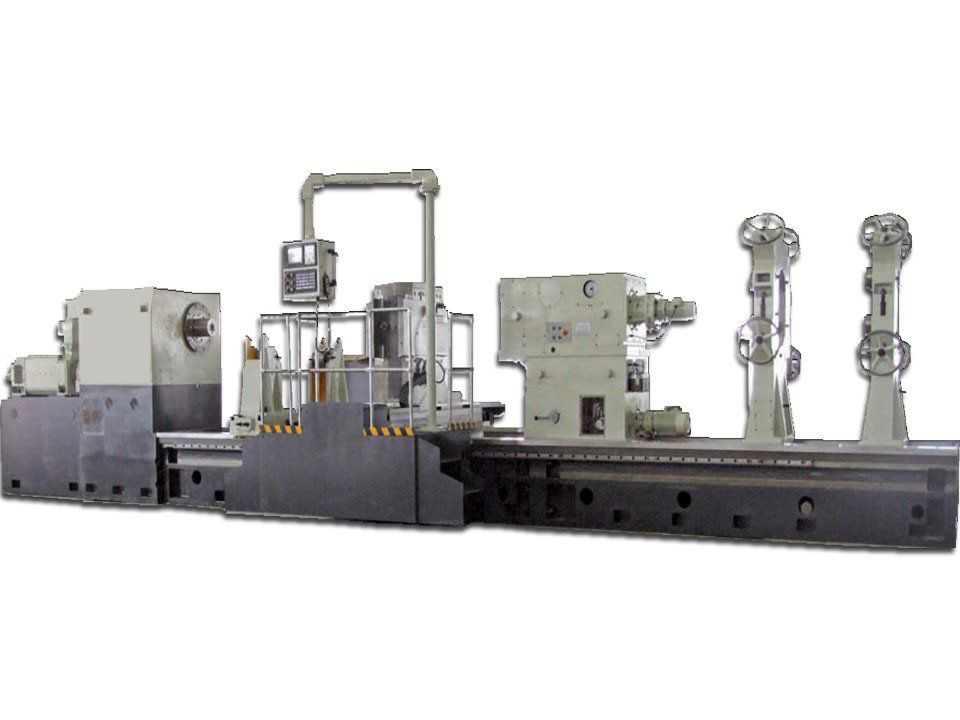

The Heavy Duty CNC Lathe 63Tons Load, Deep Hole Boring Machine, Deep Hole Honing Cutting Tool we provide is the full embodiment of the technical and comprehensive capabilities cultivated and accumulated in the course of the company's years of development. Only by being stable can it be long-lasting, and only by being strong can it be sustainable. We promise we have now the ability to offer excellent quality and reasonable price items for customers. We are always leading the industry, using innovative technologies to help our customers get safer, more effective and higher performing products.

Item | Unite | CK6146YG | CK6156YG | CK6163YG | CK6171YG | CK6180YG | |

Capacity | Max. Swing dia. over bed | mm | Φ560 | Φ630 | Φ780 | Φ1000 | Φ1050 |

Max. Swing dia. over slide | mm | Φ400 | Φ500 | Φ630 | Φ780 | Φ840 | |

Max workpiece length | mm | 2500 | 1500/2000/3000 | 2000/3000/4000 | 3000/4000/5000 | 3000/4000/5000 | |

Max turning length(cylinder) | mm | 2450 | 1450/1950/2950 | 1950/2950/3900 | 2900/3900/4900 | 2900/3900/4900 | |

Max turning diameter(shaft) | mm | Φ400 | Φ500 | Φ600 | Φ600 | Φ600 | |

Max turning diameter(plate) | mm | Φ480 | Φ600 | Φ630 | Φ780 | Φ780 | |

spindle | spindle through hole | mm | Φ80 | Φ80 | Φ90 | Φ90 | Φ90 |

Spidle inner hole taper | Metric 80# | Metric 80# | Metric 100# | Metric 100# | Metric 100# | ||

spindle nose | A2-8 | A2-8 | A2-11 | A2-11 | A2-11 | ||

spindle rotating speed range, hydraulic two shift stepless | r/min | 30-1200 | 20-1200 | 20-800 | 20-800 | 20-800 | |

main motor power | kW | 15/18.5kw | 18.5/22kw | 22/30kw | 37/42kw | 37/42kw | |

sub-spindle | Sub-spindle movement method | mm | Independent axis servo motor | Independent axis servo motor | Independent axis servo motor | Independent axis servo motor | Independent axis servo motor |

Sub-spindle sleeve diameter/travel | mm | Φ160/100 | Φ190/120 | Φ190/120 | Φ190/120 | Φ190/120 | |

chuck | Front spindle middle solid chuck diameter | mm | Φ250 | Φ315 | Φ400 | Φ500 | Φ610 |

Back spindle middle solid chuck diameter | mm | Φ200 | Φ250 | Φ315 | Φ400 | Φ500 | |

steady rest | Hydraulic steady rest clamp range | mm | Φ50-Φ250 | Φ45-Φ310/Φ85-Φ350/ Φ100-Φ320 | Φ120-Φ400/Φ230-Φ430 | Φ150-Φ500 | Φ300-Φ600 |

repeat position accuracy | mm | 0.01 | 0.01/0.01/0.01 | 0.01/0.01 | 0.01 | 0.01 | |

Tool post | Rapid movement speed (X/Z/W) | m/ min | 10/12/6 | 10/12/6 | 10/12/6 | 10/10/4 | 10/10/4 |

Travel (X/Z) | mm | 245/2500 | 315/3000 | 315/4000 | 350/5000 | 350/5000 | |

(X/Z/W) Motor torque | Nm | 11/16/11 | 22/30/12 | 22/30/12 | 22/30/12 | 22/30/12 | |

Tool post cutting tool station | 12 | 12 | 12 | 12 | 12 | ||

Outside diameter cutting tool | mm | 25×25 | 32×32 | 32×32 | 32×32 | 32×32 | |

Inner diameter cutting tool | mm | Φ50 | Φ60 | Φ60 | Φ60 &Φ80 | Φ60 &Φ80 | |

accuracy | Machining accuracy | IT6 | IT6 | IT6 | IT6 | IT6 | |

Roughness Ra | μm | 1.6 | 1.6 | 1.6 | 1.6 | 1.6 | |

Position accuracy | mm | 0.014/0.036 | 0.014/0.036 | 0.014/0.038 | 0.015/0.040 | 0.016/0.040 | |

Repeat position accuracy | mm | 0.006/0.018 | 0.006/0.018 | 0.007/0.018 | 0.007/0.020 | 0.007/0.020 | |

Weight and overall dimension | Net weight/gross weight | t | 13.5 | 18/20/22 | 22/25/28 | 28/32/34 | 28/32/36 |

Overall dimension(L*W*H) | mm | 6500×1750×1860 | 6700×2350× 2600 | 7150×2450×2650 | 7150×2550×2600 | 7150×2550×2600 | |

We rely on technological progress, strict management and quality control, thus winning a good reputation from customers, and now we have become a leader in the Special Purpose CNC Lathe for Oil Cylinder (Hydraulic cylinder) industry. With our company's confidence and strength, we keep innovating and developing steadily. And then E-mail us your specifications or inquiries today.

Welcome to send your message to us