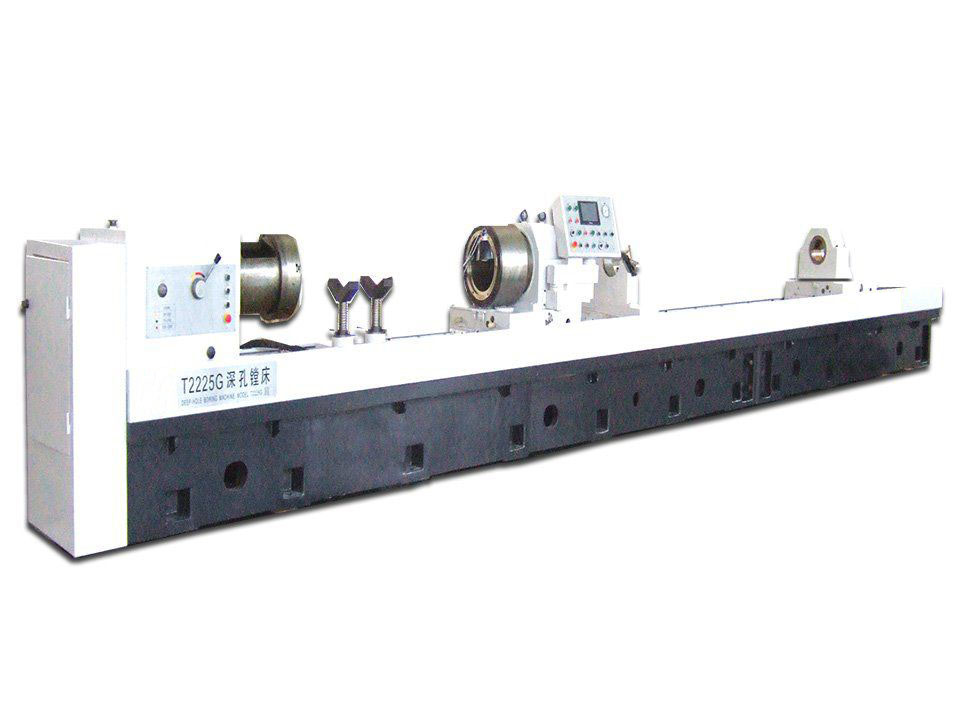

The development of our various CW/CQW Conventional Horizontal Lathes 3Tons Load, Deep Hole Drilling Boring Machine, Four Axis Deep Hole Gun Drilling Machine can basically meet the needs of the market and hold a large share in the market. Our high-end processing equipment, created the excellent quality of our products, we have a large inventory, ready to ship. Our company is good at mobilizing the enthusiasm and creativity of employees, and taking the road of enterprise group and scale operation.

Item | Unite | CK6146YG | CK6156YG | CK6163YG | CK6171YG | CK6180YG | |

Capacity | Max. Swing dia. over bed | mm | Φ560 | Φ630 | Φ780 | Φ1000 | Φ1050 |

Max. Swing dia. over slide | mm | Φ400 | Φ500 | Φ630 | Φ780 | Φ840 | |

Max workpiece length | mm | 2500 | 1500/2000/3000 | 2000/3000/4000 | 3000/4000/5000 | 3000/4000/5000 | |

Max turning length(cylinder) | mm | 2450 | 1450/1950/2950 | 1950/2950/3900 | 2900/3900/4900 | 2900/3900/4900 | |

Max turning diameter(shaft) | mm | Φ400 | Φ500 | Φ600 | Φ600 | Φ600 | |

Max turning diameter(plate) | mm | Φ480 | Φ600 | Φ630 | Φ780 | Φ780 | |

spindle | spindle through hole | mm | Φ80 | Φ80 | Φ90 | Φ90 | Φ90 |

Spidle inner hole taper | Metric 80# | Metric 80# | Metric 100# | Metric 100# | Metric 100# | ||

spindle nose | A2-8 | A2-8 | A2-11 | A2-11 | A2-11 | ||

spindle rotating speed range, hydraulic two shift stepless | r/min | 30-1200 | 20-1200 | 20-800 | 20-800 | 20-800 | |

main motor power | kW | 15/18.5kw | 18.5/22kw | 22/30kw | 37/42kw | 37/42kw | |

sub-spindle | Sub-spindle movement method | mm | Independent axis servo motor | Independent axis servo motor | Independent axis servo motor | Independent axis servo motor | Independent axis servo motor |

Sub-spindle sleeve diameter/travel | mm | Φ160/100 | Φ190/120 | Φ190/120 | Φ190/120 | Φ190/120 | |

chuck | Front spindle middle solid chuck diameter | mm | Φ250 | Φ315 | Φ400 | Φ500 | Φ610 |

Back spindle middle solid chuck diameter | mm | Φ200 | Φ250 | Φ315 | Φ400 | Φ500 | |

steady rest | Hydraulic steady rest clamp range | mm | Φ50-Φ250 | Φ45-Φ310/Φ85-Φ350/ Φ100-Φ320 | Φ120-Φ400/Φ230-Φ430 | Φ150-Φ500 | Φ300-Φ600 |

repeat position accuracy | mm | 0.01 | 0.01/0.01/0.01 | 0.01/0.01 | 0.01 | 0.01 | |

Tool post | Rapid movement speed (X/Z/W) | m/ min | 10/12/6 | 10/12/6 | 10/12/6 | 10/10/4 | 10/10/4 |

Travel (X/Z) | mm | 245/2500 | 315/3000 | 315/4000 | 350/5000 | 350/5000 | |

(X/Z/W) Motor torque | Nm | 11/16/11 | 22/30/12 | 22/30/12 | 22/30/12 | 22/30/12 | |

Tool post cutting tool station | 12 | 12 | 12 | 12 | 12 | ||

Outside diameter cutting tool | mm | 25×25 | 32×32 | 32×32 | 32×32 | 32×32 | |

Inner diameter cutting tool | mm | Φ50 | Φ60 | Φ60 | Φ60 &Φ80 | Φ60 &Φ80 | |

accuracy | Machining accuracy | IT6 | IT6 | IT6 | IT6 | IT6 | |

Roughness Ra | μm | 1.6 | 1.6 | 1.6 | 1.6 | 1.6 | |

Position accuracy | mm | 0.014/0.036 | 0.014/0.036 | 0.014/0.038 | 0.015/0.040 | 0.016/0.040 | |

Repeat position accuracy | mm | 0.006/0.018 | 0.006/0.018 | 0.007/0.018 | 0.007/0.020 | 0.007/0.020 | |

Weight and overall dimension | Net weight/gross weight | t | 13.5 | 18/20/22 | 22/25/28 | 28/32/34 | 28/32/36 |

Overall dimension(L*W*H) | mm | 6500×1750×1860 | 6700×2350× 2600 | 7150×2450×2650 | 7150×2550×2600 | 7150×2550×2600 | |

We believe that our Special Designed Horizontal CNC Lathe for Oil Pipes (CG61160) can compete with any other similar products in terms of quality performance as well as price. We adhere to the development strategy of "high specialization and moderate diversification" and are committed to employee growth, customer satisfaction and corporate development. Our employees can always maintain full of energy and enthusiasm for the enterprise dedication.

Welcome to send your message to us