Sinotruk HOWO Concrete Mixing Truck Heavy Duty 6X4 336 371HP 8 9 10 12m3 Cement Concrete ...

The usage of 2M2125A 2M2135A Deep Hole Honing Machine is a special equipment used for honing cylindrical deep hole parts such as various hydraulic oil cylinders and cylinders. Hole Diameter accuracy of machined workpieces can be up to or over IT7 and surface roughness Ra0.2-0.4μm. It can also repair and maintain taper and ellipticity of machined workpieces with the help of partial honing.

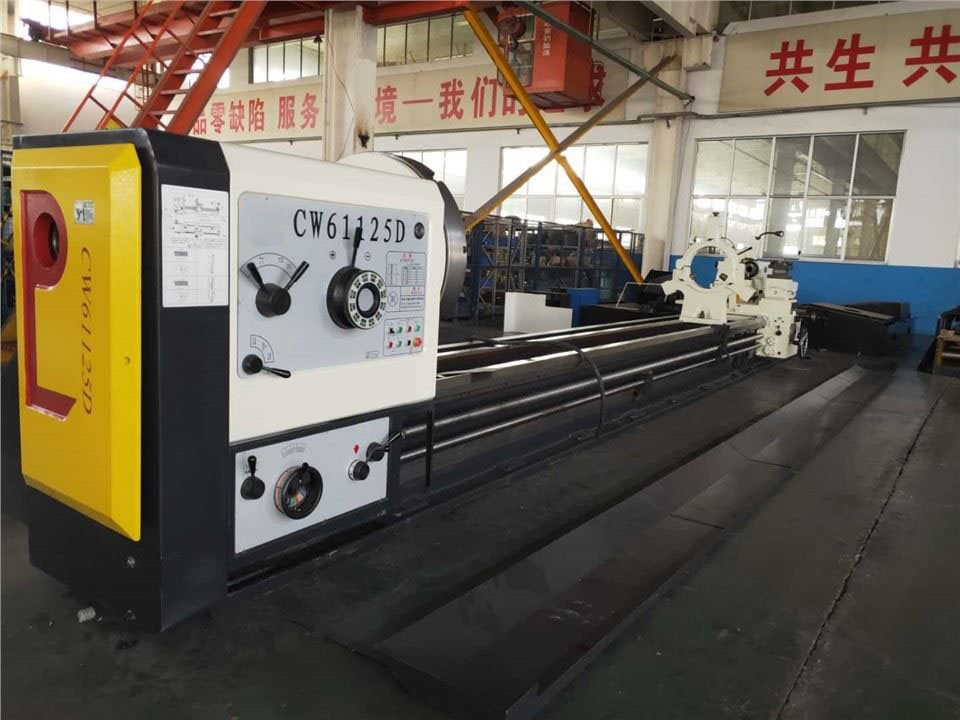

We will maintain and leverage the existing strengths to further improve our CNC Horizontal Lathe, Heavy Duty CNC Lathe 63Tons Load, CW H Series Heavy Duty Horizontal Lathe Machine 20Tons Load and expand our business areas. The company clarifies that product quality and service are the only core competitiveness, and vigorously promotes the brand and builds brand awareness, making it a well-known brand in the global industry. We are open-minded to listen to and accept customers' valuable opinions, devote ourselves to research and innovation, and strive to save customers' worry, time and effort.

The usage of 2M2125A 2M2135A Deep Hole Honing Machine is a special equipment used for honing cylindrical deep hole parts such as various hydraulic oil cylinders and cylinders. Hole Diameter accuracy of machined workpieces can be up to or over IT7 and surface roughness Ra0.2-0.4μm. It can also repair and maintain taper and ellipticity of machined workpieces with the help of partial honing.

This machine is match with KND,SIEMENS, FANUC CNC system.AC servo motor, honing box adopt stepless speed, Autocycle timing control unit is used on this machine during reciprocating honing so as to assure accuracy of machined holes and decrease the intensity of labour.

Sand blades and workpieces always maintain constant pressure during honing. It is a feature of high efficiency and strong cutting force. It can perform rough and finished honing of general cylindrical deephole parts after rough- boring. It can directly perform high efficiency honing of cold drawing steel pipes. Traditional deep hole processing is simplified by using this machine.

Productivity is greatly increased. Materials of honed workpieces may be casting iron or all kinds of steel including quench parts. Cooling system of this machine adopts the method of three-step filtering in order to assure clearing of coolant.

This machine is controlled by electrical operating center. It is easy, safe and reliable in operation.

It can perform not only honing of mass products but also small batch workpieces. It is perfect equipment for machining deep hole parts.

Specification | Parameter | |

2M2125A | 2M2135A | |

Honing diameter range | φ40-φ250 | φ80-φ350 |

Maximum honing depth | 8000 | 12000 |

Center height | 350 | 350 |

Diameter range of clamping workpiece | φ60-φ350 | φ100-φ420 |

Spindle speed range of grinding rod box | 25-250r/min | 25-250r/min |

Reciprocating speed range of grinding rod box | 3-20m/min | 3-20m/min |

Motor power of grinding rod box | 7.5kW( frequency motor) | 15kW(frequency motor) |

Oil pump flow of grinding head expansion hydraulic system | 12.5L/min | 12.5L/min |

Maximum working pressure of oil pump in grinding head expansion hydraulic system | 4MPa | 4MPa |

Cooling pump flow | 50L/min | 100L/min |

Cooling tank volume | 950L | 950L |

Power of oil pump motor of grinding head expansion hydraulic system | 1.1kW | 1.1kW |

Cooling pump motor power | 2.2kW | 2.2kW(TWO GROUP) |

Reciprocating motor power | 5.5kW | 7.5kW |

We continue to enrich product types, complete product specifications and models, aiming to create a professional one-stop Sinotruk HOWO Concrete Mixing Truck Heavy Duty 6X4 336 371HP 8 9 10 12m3 Cement Concrete ... platform. We are committed to the main indicators into the world's leading similar enterprises, so that we can have our own global competitiveness. The company insists on leading reform and development with ideological emancipation, and accelerates reform and development with open cooperation.

Welcome to send your message to us