Monthly Deals 500mm Horizontal 35 Degree Incline Slant Bed Brake CNC Lathe Machine

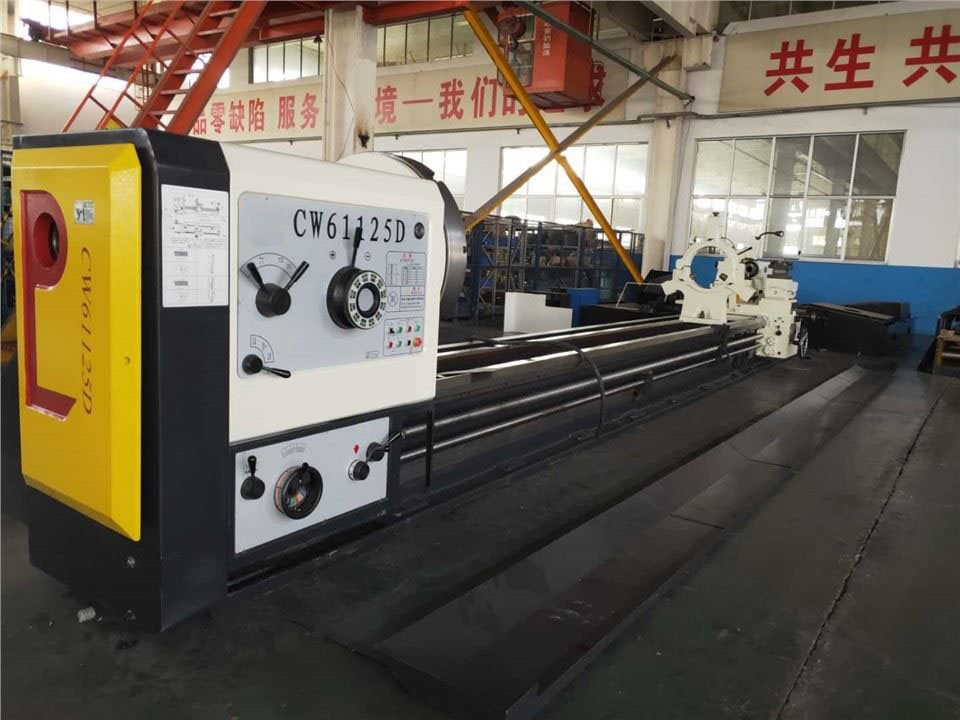

CW-D Series Horizontal Lathe Machine 6Tons Load can perform to turn end faces, cylindrical surfaces and internal holes of various parts as well as metric, inch, module and pitch threads.

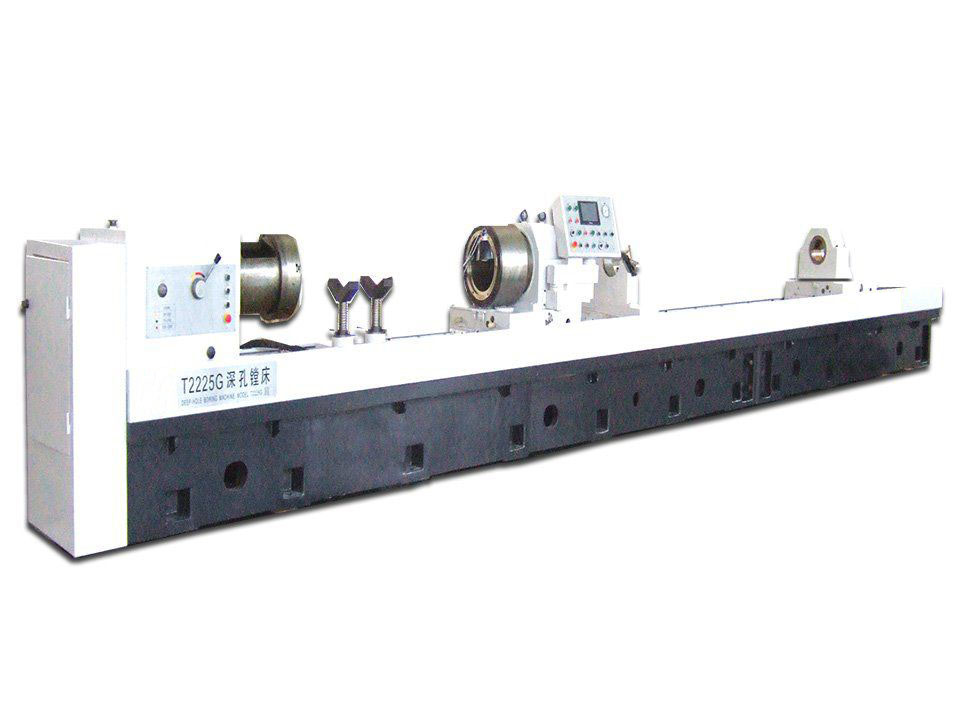

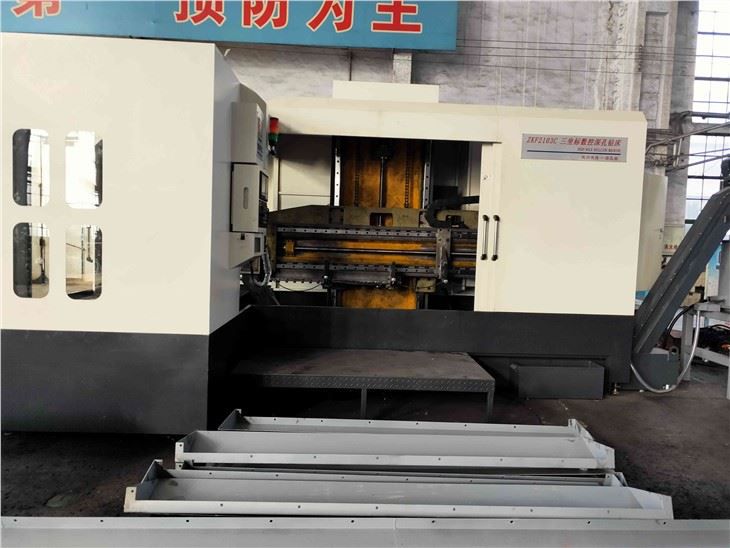

Our company pursues the quality of survival, innovation and development of business strategy, in line with the customer first sales philosophy, to provide users with better and newer Deep Hole Cutting Tool, CNC Heavy Duty Lathe 25Tons Load, Slant Bed CNC Lathe. Since its establishment, the company has been pursuing and absorbing cutting-edge technology and craftsmanship in the industry, and continuously innovating. We pursue the maximization of customer benefits, the pursuit of high-quality and satisfactory services, the pursuit of a sustainable development strategy, and the pursuit of a people-oriented way of survival. In the selection and use of talents we always adhere to the scientific and reasonable way to maximize the value of human resources.

CW-D Series Horizontal Lathe Machine 6Tons Load can perform to turn end faces, cylindrical surfaces and internal holes of various parts as well as metric, inch, module and pitch threads. The top slides can be operated individually by power for cutting short taper surface also, can be turned automatically through the compound movement combining longitudinal feed with the top slide feed, moreover, the machines may be used for drilling, boring and trepanning. They are characteristics of power, high spindle speed, high rigidity.

The various ferrous and non ferrous metals parts may be turned through the heavy cutting by carbon alloy tools.

Technology Parameter

Specification | CW61100D | CW61125D | CW61140D | CW61160D | |

Capacity | Swing dia. over bed | Φ1040 | Φ1290 | Φ1440 | Φ1640 |

Swing dia. over cross slide | Φ650 | Φ900 | Φ1030 | Φ1030 | |

Width of bed | 755mm | ||||

Max center distance between center | 1000mm-16000mm | ||||

The max workpiece bearing weight between two centers | 6000kg | ||||

Spindle | Spindle nose | A2-15 | |||

Spindle bore diameter | 120mm 130mm (special order) | ||||

Taper of spindle bore | Metric No. 140 | ||||

Range of spindle speed | 3.15-315r/min 21 kinds(forwards) | ||||

Spindle front bearing inner diameter | Φ200mm | ||||

Feeds | Longitudinal feeds range | 0.1-12mm/r 56 kinds | |||

Transversal feed range | 0.05-6mm/r 56kinds | ||||

Metric tread range | 1-120mm 44kinds | ||||

Inch tread range | 3/8-28teeth/inch 31kinds | ||||

Modular thread range | 0.5—60mm 45kinds | ||||

Pitch thread range | 1-56teeth/inch 25 kinds | ||||

Tailstock | Tailstock center taper | METRIC 80MM | |||

Travel of the tailstock sleeve | 300mm | ||||

Tailstock center sleeve | Φ160mm | ||||

Motors | Main motor power | 22kw | |||

rapid motor power | 1.5kw | ||||

Cool pump power | 0.125kw | ||||

Standard Accessories

Four-jaw chuck φ1000mm 1set | Steady rest (70-480mm) 1set | Foundation screws 1set |

Morse 6# center 1set | Center sleeve 1set | Tools 1set |

Follow rest φ50-220mm 1set |

|

|

Document with Machine for One Machine Tool

Content | Document | Number | Note |

1 | Operational manuals | 1 | Mechanical and electrical |

2 | Acceptance of certificate | 1 |

|

3 | Packing list | 1 |

We are constantly engaged in the development of new products to improve our corporate goals and to design and produce Monthly Deals 500mm Horizontal 35 Degree Incline Slant Bed Brake CNC Lathe Machine for our customers according to their requirements. Our company takes 'highlighting specialization, optimizing regionalization, realizing differentiation' as the development idea, implements rational management and continues to maintain a rapid development speed. We continue to improve the construction of a democratic management system and effectively implement the fundamental policy of wholeheartedly relying on employees to run enterprises.

Welcome to send your message to us