Large Double Column Vertical PLC Lathe Turning Machine for Wind Power

The workbench and workbench base adopts the whole casting structure with high strength and low stress casting, so it has enough stiffness, strength and thermal stability. And the casting part willl be by second time aging treatment, so as to eliminate stress and ensure the precision of the machine tool for the long-term stability and stability.

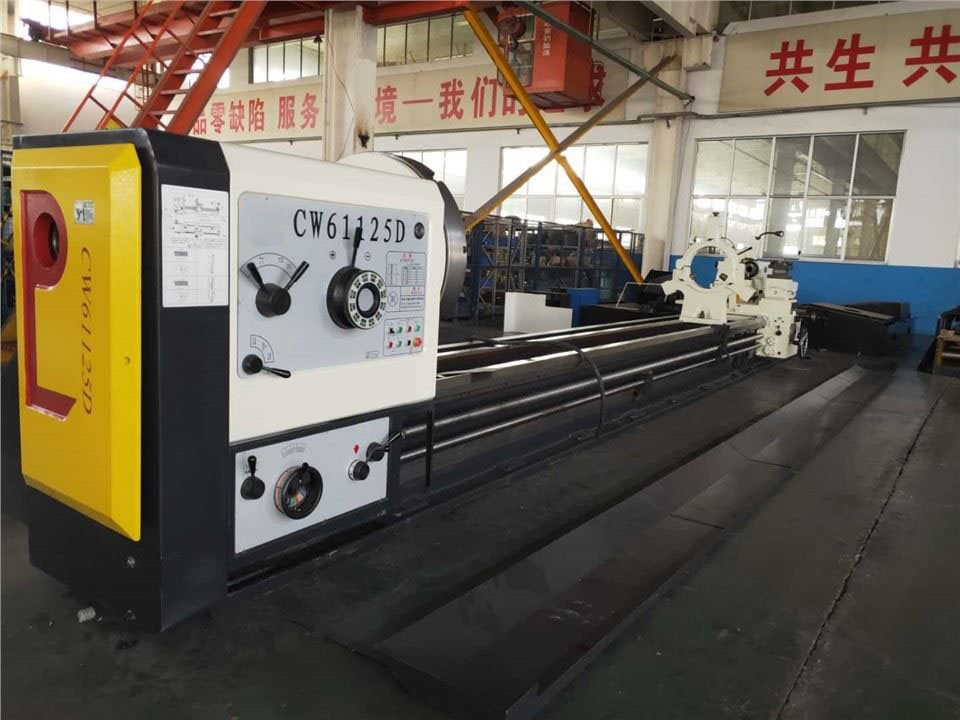

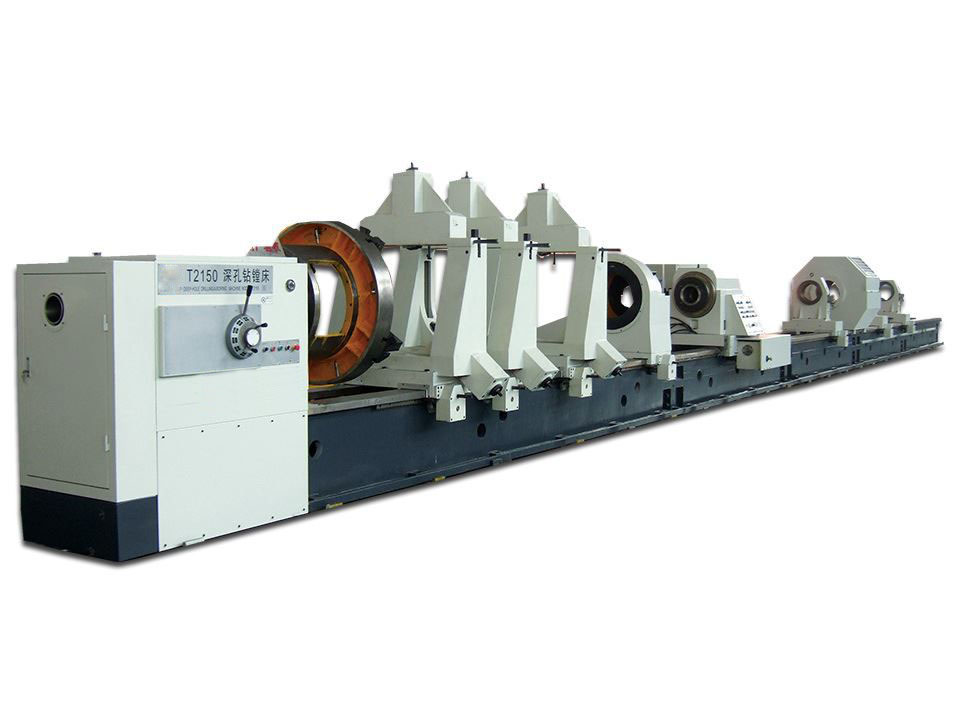

We thinks what customers think, the urgency of urgency to act during the interests of a purchaser position of theory, allowing for much better good quality, lower processing costs, prices are extra reasonable, won the new and old buyers the support and affirmation for T2120G Deep Hole Drilling And Boring Machine, Heavy Duty CNC Lathe Machine 80Tons Load, CW CQW Conventional Horizontal Lathes 3Tons Load. Material purchase is the premise and foundation of production and operation of an enterprise. Only by strengthening material purchase management, reducing material purchase cost and improving material purchase quality can the economic benefits of an enterprise be improved. For the specific requirements of different customers, our team is able to fully meet the customer's product needs and manufacturing process, so as to tailor specific for customers. Our company's products have been widely used in many fields and we have become the industry leader.

1.The workbench adopts constant current hydrostatic guideway, which has high working accuracy and strong bearing capacity.

2.The spindle adopts short spindle structure, spindle centering bearing uses double row roller bearings with high accuracy.

3.The main movement adopts AC servo motor or DC motor drive, stepless speed within two level.

4. Tool post uses high rigid rectangular ram with single knief holder structure.

5.Workbench adopts manual four jaw chuck.

6. Machine tool can choose cooling device, automatic chip removal machine, protective device, as optional parts, etc

7. The common tool post is controlled as PLC with LCD screen display, manual pulse tool control the movement of cutting tool.

8. CNC machine can choose domestic or imported numerical control system, also can equip with graing ruler.

9.The tool post can be equipped with milling head or grinding head for multi-usage.

10.The beam guide rail is treated by quenching and grinding processing.

Item | Model | C5240*H*40 | C5250*H*40 | C5263*H*40 |

Max turning diameter | mm | 4000 | 5000 | 6300 |

Max workpiece height | mm | 2000/2500/3150 | 2000/2500/3150 | 2000/3150/3500 |

Workbench diameter | mm | 3500 | 4000 | 4500 |

Max workpiece weight | Tons | 40/50 | ||

Workbench rpm level | Two stepless speed | Two stepless speed | Two stepless speed | |

Workbench rpm range | r/min | I档0.4-13.3/ | I档0.4-13.3/ | I档0.4-13.3/ |

tool post feed speed | mm/min | 4000 | 4000 | 4000 |

tool post feed speed range | mm/min | 0.5~1000 | 0.5~1000 | 0.5-1000 |

Ram cross face | mm | 240*240 | 240*240 | 240*240 |

main motor power | kW | 75 | ||

machine tool weight | t | 95/97/100 | 100/102/105 | 105/113/120 |

We have been listening to customers' demands and actively developing new Large Double Column Vertical PLC Lathe Turning Machine for Wind Power. Our company adheres to technological innovation and constantly pays attention to, tracks and grasps new technologies. We solemnly promise that we will continue to forge ahead and return the support and attention of domestic and foreign customers to our company with professional products and services.

Welcome to send your message to us