Large Double Column Siemens CNC Vertical Turning Lathe Machine for Wind Power CK5225 CK5231

The workbench and workbench base adopts the whole casting structure with high strength and low stress casting, so it has enough stiffness, strength and thermal stability. And the casting part willl be by second time aging treatment, so as to eliminate stress and ensure the precision of the machine tool for the long-term stability and stability.

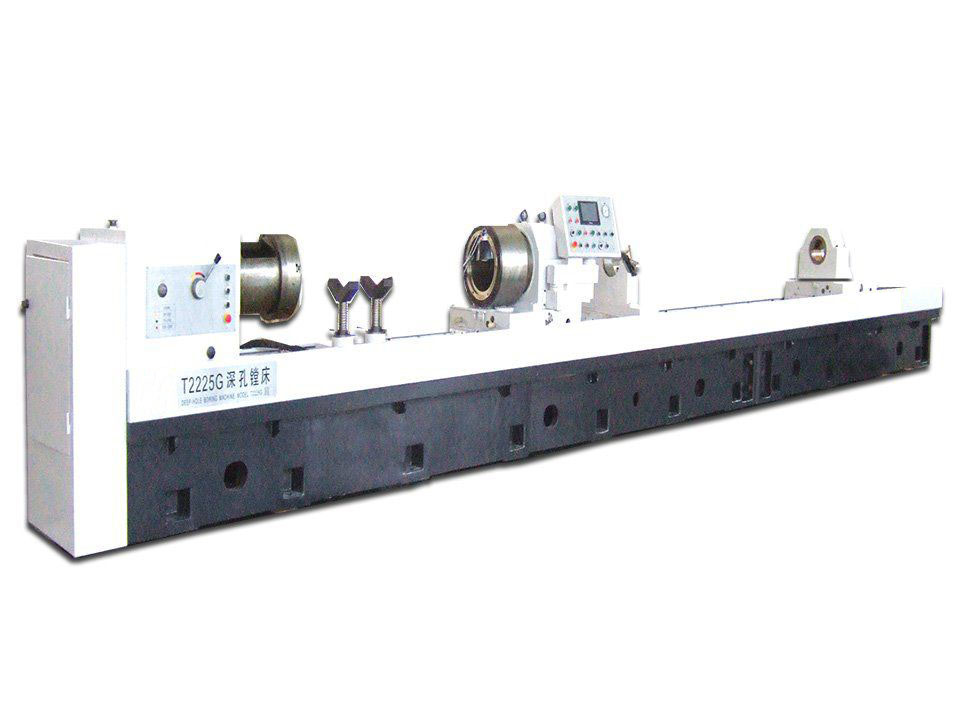

We have been committed to becoming an excellent 2M2125A 2M2135A Deep Hole Honing Machine, CKD D Series High Precision CNC Lathe 6Tons Load, Welding Bed Honing Machine supplier, providing customers with high-quality products, services and solutions. We will pour into our enthusiasm to provide our customers with better services and products. The company always takes the management concept of "differentiated production and high-end operation" as its guideline and vigorously advocates the enterprise spirit of "innovation makes a big difference". We take the principle of openness, fairness and justice, and combine the needs of the strategic development of the enterprise to provide planned training for employees.

1.The workbench adopts constant current hydrostatic guideway, which has high working accuracy and strong bearing capacity.

2.The spindle adopts short spindle structure, spindle centering bearing uses double row roller bearings with high accuracy.

3.The main movement adopts AC servo motor or DC motor drive, stepless speed within two level.

4. Tool post uses high rigid rectangular ram with single knief holder structure.

5.Workbench adopts manual four jaw chuck.

6. Machine tool can choose cooling device, automatic chip removal machine, protective device, as optional parts, etc

7. The common tool post is controlled as PLC with LCD screen display, manual pulse tool control the movement of cutting tool.

8. CNC machine can choose domestic or imported numerical control system, also can equip with graing ruler.

9.The tool post can be equipped with milling head or grinding head for multi-usage.

10.The beam guide rail is treated by quenching and grinding processing.

Item | Model | C5240*H*40 | C5250*H*40 | C5263*H*40 |

Max turning diameter | mm | 4000 | 5000 | 6300 |

Max workpiece height | mm | 2000/2500/3150 | 2000/2500/3150 | 2000/3150/3500 |

Workbench diameter | mm | 3500 | 4000 | 4500 |

Max workpiece weight | Tons | 40/50 | ||

Workbench rpm level | Two stepless speed | Two stepless speed | Two stepless speed | |

Workbench rpm range | r/min | I档0.4-13.3/ | I档0.4-13.3/ | I档0.4-13.3/ |

tool post feed speed | mm/min | 4000 | 4000 | 4000 |

tool post feed speed range | mm/min | 0.5~1000 | 0.5~1000 | 0.5-1000 |

Ram cross face | mm | 240*240 | 240*240 | 240*240 |

main motor power | kW | 75 | ||

machine tool weight | t | 95/97/100 | 100/102/105 | 105/113/120 |

We implement the development strategy of 'people-oriented, serving users', and continue to devote ourselves to product quality improvement and cost control, to provide customers with high-quality Large Double Column Siemens CNC Vertical Turning Lathe Machine for Wind Power CK5225 CK5231 and considerate services. We have a comprehensive understanding and mastery of the industrial supply chain, and we provide services with high knowledge and technical content. Our company has sufficient supply and timely supply and our goods will arrive at the port on time.

Welcome to send your message to us