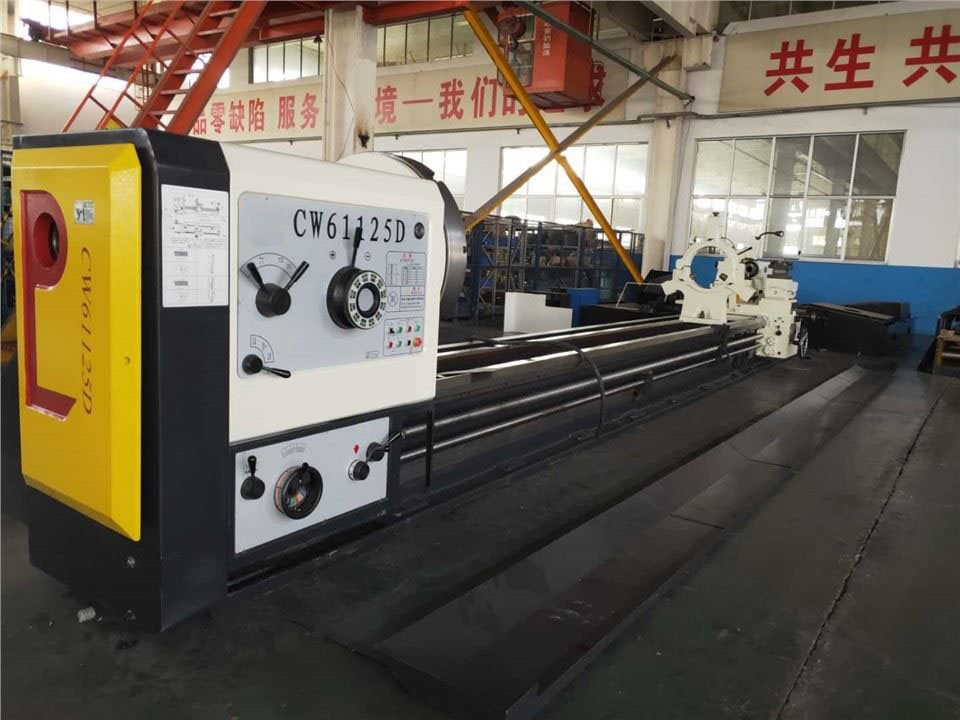

Horizontal Ecnomical High Precision Flat Bed Automatic Metal Cutting CNC Turning Lathe Machine

CW-D Series Horizontal Lathe Machine 6Tons Load can perform to turn end faces, cylindrical surfaces and internal holes of various parts as well as metric, inch, module and pitch threads.

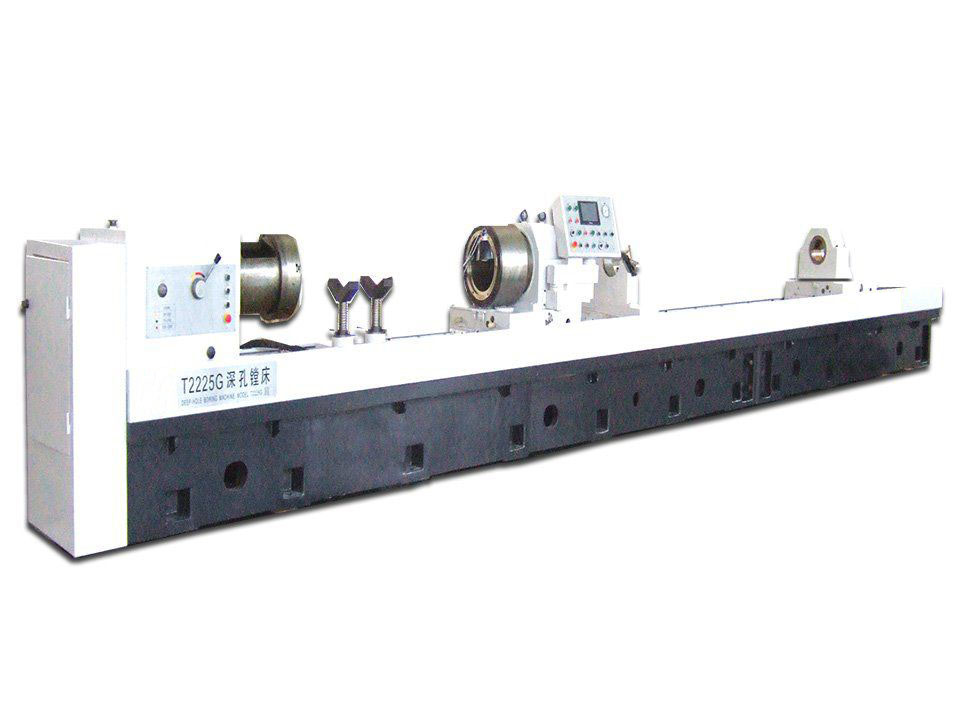

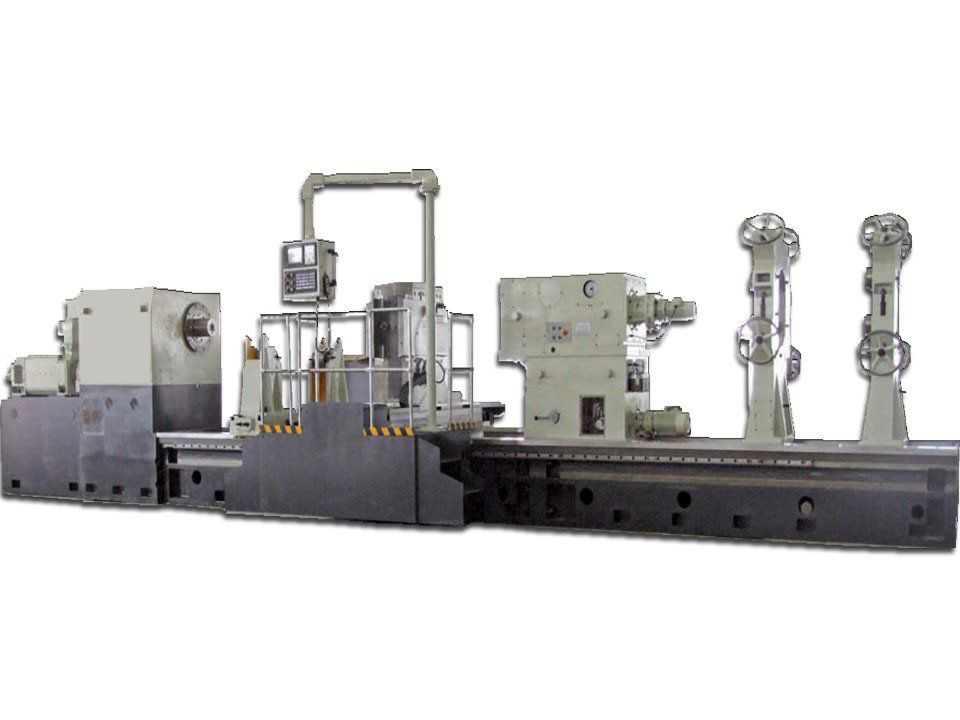

Through continuous development, we have mastered the advanced, energy-saving and environment-friendly product design and manufacturing technology of the Deep Hole Gun Drilling Machine, CNC High Precision Lathe, Conventional Horizontal Lathes in the industry. We are able to do your tailored get to fulfill your own satisfactory! sets up several departments, including manufacturing department, sales department, high quality control department and sevice center, etc. We advocate the joy of working and living happily, and through the provision of products and services, we ultimately allow our customers to reap care, satisfaction, value and happiness. The company emphasizes the concept of people-oriented, scientific management, and respects the professionalism of pragmatic and pioneering work.

CW-D Series Horizontal Lathe Machine 6Tons Load can perform to turn end faces, cylindrical surfaces and internal holes of various parts as well as metric, inch, module and pitch threads. The top slides can be operated individually by power for cutting short taper surface also, can be turned automatically through the compound movement combining longitudinal feed with the top slide feed, moreover, the machines may be used for drilling, boring and trepanning. They are characteristics of power, high spindle speed, high rigidity.

The various ferrous and non ferrous metals parts may be turned through the heavy cutting by carbon alloy tools.

Technology Parameter

Specification | CW61100D | CW61125D | CW61140D | CW61160D | |

Capacity | Swing dia. over bed | Φ1040 | Φ1290 | Φ1440 | Φ1640 |

Swing dia. over cross slide | Φ650 | Φ900 | Φ1030 | Φ1030 | |

Width of bed | 755mm | ||||

Max center distance between center | 1000mm-16000mm | ||||

The max workpiece bearing weight between two centers | 6000kg | ||||

Spindle | Spindle nose | A2-15 | |||

Spindle bore diameter | 120mm 130mm (special order) | ||||

Taper of spindle bore | Metric No. 140 | ||||

Range of spindle speed | 3.15-315r/min 21 kinds(forwards) | ||||

Spindle front bearing inner diameter | Φ200mm | ||||

Feeds | Longitudinal feeds range | 0.1-12mm/r 56 kinds | |||

Transversal feed range | 0.05-6mm/r 56kinds | ||||

Metric tread range | 1-120mm 44kinds | ||||

Inch tread range | 3/8-28teeth/inch 31kinds | ||||

Modular thread range | 0.5—60mm 45kinds | ||||

Pitch thread range | 1-56teeth/inch 25 kinds | ||||

Tailstock | Tailstock center taper | METRIC 80MM | |||

Travel of the tailstock sleeve | 300mm | ||||

Tailstock center sleeve | Φ160mm | ||||

Motors | Main motor power | 22kw | |||

rapid motor power | 1.5kw | ||||

Cool pump power | 0.125kw | ||||

Standard Accessories

Four-jaw chuck φ1000mm 1set | Steady rest (70-480mm) 1set | Foundation screws 1set |

Morse 6# center 1set | Center sleeve 1set | Tools 1set |

Follow rest φ50-220mm 1set |

|

|

Document with Machine for One Machine Tool

Content | Document | Number | Note |

1 | Operational manuals | 1 | Mechanical and electrical |

2 | Acceptance of certificate | 1 |

|

3 | Packing list | 1 |

Based on the business philosophy of 'Thinking for customers', the company brings together a large number of experts who have been developing in the Horizontal Ecnomical High Precision Flat Bed Automatic Metal Cutting CNC Turning Lathe Machine industry for many years and serve the society wholeheartedly. Our production equipment and mature production technology ensure the same quality, faster delivery period and higher cost performance. We insist on doing everything we should do seriously and grasp every opportunity, we can make the company develop better and better.

Welcome to send your message to us