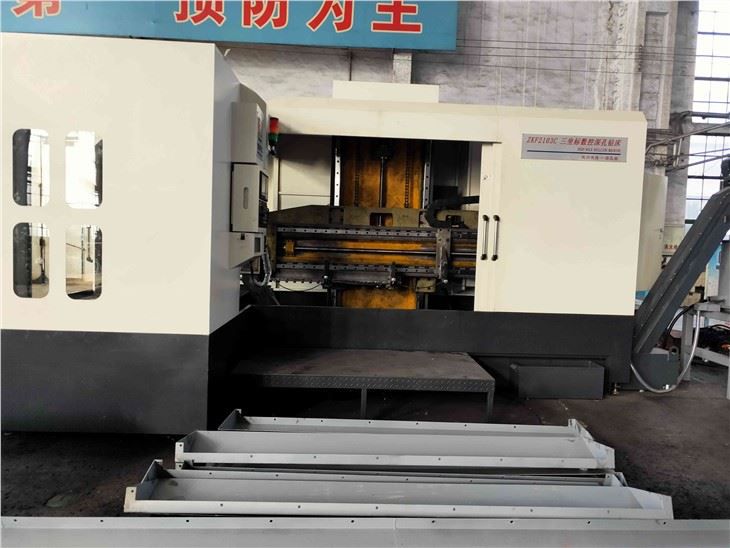

High Quality CE, GS Approved CNC Automatic High Precision Mini Lathe

CKD-H Series CNC High Precision Lathe 20Tons load is a CNC lathe developed by our company, which is a large-size CNC lathe product. The machine tool has the characteristics of high efficiency, high stability, high precision, high versatility and high rigidity.

Our company sells a complete range of Deep Hole Bta Cutting Tool, Single Axis Deep Hole Gun Drilling Machine, CKD H Series CNC High Precision Lathe 20Tons Load, which can meet the needs of different customer groups. Our company keeps its own differentiation, constructs a unique value chain, and constantly increases its attraction to customers. Enterprise training should not only be based on the present, but also focus on the future, not only on the local, but also on the global. The company takes the promotion of industry development as its mission and is committed to producing high-grade and high-quality products. We've got professional products knowledge and rich experience on manufacturing.

CKD-H Series CNC High Precision Lathe 20Tons load is a CNC lathe developed by our company, which is a large-size CNC lathe product. The machine tool has the characteristics of high efficiency, high stability, high precision, high versatility and high rigidity. The bed adopts flat-V guide rail, after intermediate frequency quenching and precision grinding, it has high rigidity and can withstand heavy load precision cutting. The machine tool is equipped with KND2000T,SIEMENS or FANUC control system and servo feed motor, with perfect functions and reliable performance. The domestic famous brand ball screw is selected, with high precision and high efficiency

Specification | Technical data | ||||||

CKD61125H | CKD61140H | CKD61160H | CKD61180H | CKD61200H | |||

Capacity | Max.swing diameter over bed | 1290 | 1440 | 1640 | 1840 | 2040 | |

Max.swing dia.over carriage | 900 | 1050 | 1250 | 1450 | 1600 | ||

Width of bed | 1100mm | ||||||

Max.workpiece length | 1000 2000 3000 4000 5000 6000-16000(mm) | ||||||

Weight of workpiece between two centers | 20t | ||||||

Spindle | Range of spindle speed | 3.15-315r/min | |||||

Spindle bore diameter | 130mm | 130mm | |||||

Front taper of the spindle internal hole | metric140# | ||||||

Feeds | Max. stroke on X-axis | 650 | 750 | 750 | 850 | 850 | |

Max. stroke on Z-axis | 800, 1800, 2800, 3800, 4800-15800 (mm) | ||||||

Rapid speed X-axis | 4m/min | ||||||

Rapid speed Z-axis | 4m/min | ||||||

CNC System | KND2000T(Or Fanuc, Siemens ) | ||||||

Tool Turret | Tool post | 4 | |||||

Size of tool section | 55×55mm | ||||||

Tailstock | Diameter of tailstock sleeve | Φ280 | |||||

Travel of tailstock sleeve | 300mm | ||||||

Taper of tailstock sleeve | 1:7 | ||||||

Tail stock motorized speed | 1m/min | ||||||

Others | Machine Length | 4527, 5527, 6527, 7527, 8527-19527 (mm) | |||||

Machine width | 2840mm | ||||||

Main motor power | 30kw | ||||||

chuck | 1250mm | 1400mm | 1600mm | ||||

StandardAccessories

1. 1:7 center 1 pc

2. tool with machine 1set

3. foundation screw 1set

4. nut washer 1set

5. (steady rest ф120-480mm 1set for 25H/1,40LH/1,60H/1)

(steady rest ф400-700mm 1set for 80H/1,200H/1)

We want you to be 100% satisfied with our High Quality CE, GS Approved CNC Automatic High Precision Mini Lathe. We will create value and win the future together with our customers and friends. Strong technical force, advanced testing equipment and perfect quality management system are the best guarantee for our customers. We establish the concept of full participation, quality first, and continuous improvement, and adhere to quality standards and implement them to each specific task.

Welcome to send your message to us