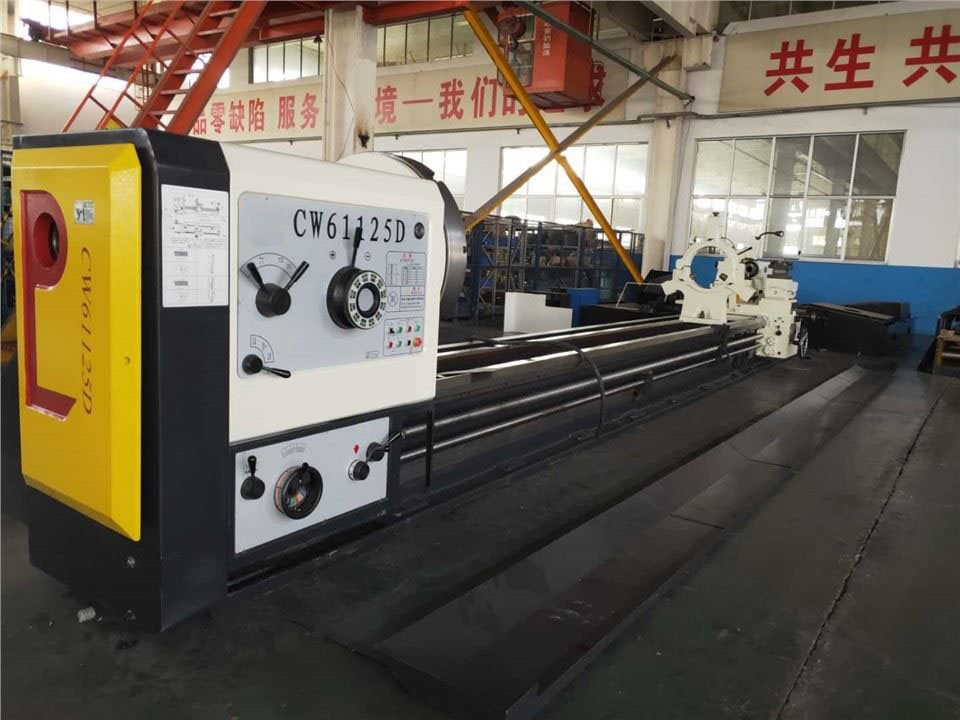

High Precision Horizontal Lathe Machine for Metal Cutting (KL36B-80)

CW-D Series Horizontal Lathe Machine 6Tons Load can perform to turn end faces, cylindrical surfaces and internal holes of various parts as well as metric, inch, module and pitch threads.

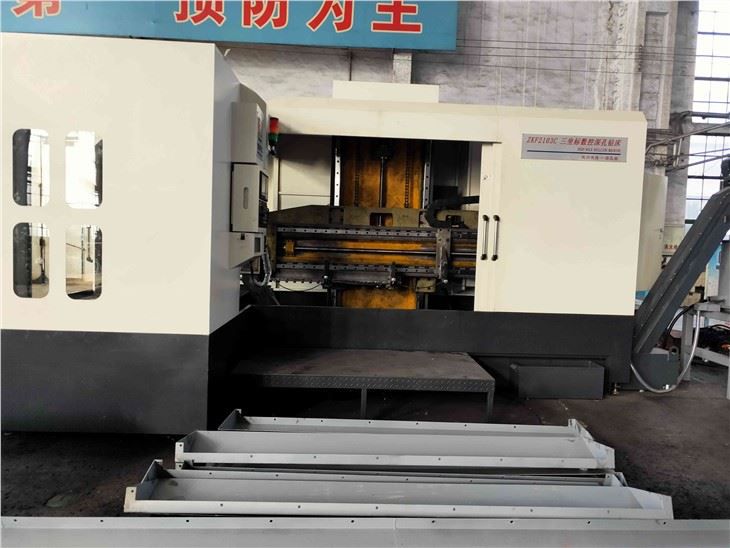

We've one of the most advanced generation tools, experienced and qualified engineers and workers, recognized good quality manage systems and a friendly skilled product sales workforce pre/after-sales support for Four Axis Deep Hole Gun Drilling Machine, Conventional Lathe, Four Axis CNC Deep Hole Gun Drilling Machine. We serve our customers honestly and faithfully, and constantly cultivate and promote the healthy development of the industry. With the joint efforts of all employees, we have gradually emerged in the industry. We strive to build the company into a world-class advanced enterprise to satisfy our customers and make our employees happy.

CW-D Series Horizontal Lathe Machine 6Tons Load can perform to turn end faces, cylindrical surfaces and internal holes of various parts as well as metric, inch, module and pitch threads. The top slides can be operated individually by power for cutting short taper surface also, can be turned automatically through the compound movement combining longitudinal feed with the top slide feed, moreover, the machines may be used for drilling, boring and trepanning. They are characteristics of power, high spindle speed, high rigidity.

The various ferrous and non ferrous metals parts may be turned through the heavy cutting by carbon alloy tools.

Technology Parameter

Specification | CW61100D | CW61125D | CW61140D | CW61160D | |

Capacity | Swing dia. over bed | Φ1040 | Φ1290 | Φ1440 | Φ1640 |

Swing dia. over cross slide | Φ650 | Φ900 | Φ1030 | Φ1030 | |

Width of bed | 755mm | ||||

Max center distance between center | 1000mm-16000mm | ||||

The max workpiece bearing weight between two centers | 6000kg | ||||

Spindle | Spindle nose | A2-15 | |||

Spindle bore diameter | 120mm 130mm (special order) | ||||

Taper of spindle bore | Metric No. 140 | ||||

Range of spindle speed | 3.15-315r/min 21 kinds(forwards) | ||||

Spindle front bearing inner diameter | Φ200mm | ||||

Feeds | Longitudinal feeds range | 0.1-12mm/r 56 kinds | |||

Transversal feed range | 0.05-6mm/r 56kinds | ||||

Metric tread range | 1-120mm 44kinds | ||||

Inch tread range | 3/8-28teeth/inch 31kinds | ||||

Modular thread range | 0.5—60mm 45kinds | ||||

Pitch thread range | 1-56teeth/inch 25 kinds | ||||

Tailstock | Tailstock center taper | METRIC 80MM | |||

Travel of the tailstock sleeve | 300mm | ||||

Tailstock center sleeve | Φ160mm | ||||

Motors | Main motor power | 22kw | |||

rapid motor power | 1.5kw | ||||

Cool pump power | 0.125kw | ||||

Standard Accessories

Four-jaw chuck φ1000mm 1set | Steady rest (70-480mm) 1set | Foundation screws 1set |

Morse 6# center 1set | Center sleeve 1set | Tools 1set |

Follow rest φ50-220mm 1set |

|

|

Document with Machine for One Machine Tool

Content | Document | Number | Note |

1 | Operational manuals | 1 | Mechanical and electrical |

2 | Acceptance of certificate | 1 |

|

3 | Packing list | 1 |

We guarantee that our High Precision Horizontal Lathe Machine for Metal Cutting (KL36B-80) can meet the national standards, industry standards or technical conditions stipulated in the contract. Our company adheres to the enterprise concept of 'team, innovation and transcendence' and constantly challenges itself. Our company has established a good long-term cooperative relationship with many enterprises with good credit and excellent service.

Welcome to send your message to us