Heavy Duty Horizontal Lathe, Lathe Machine for Turning Steel Roll, Crankshaft, Cylinder,

CW-N Series Heavy Duty Lathe Machine 25Tons Load can perform to turn end faces, cylindrical surfaces and internal holes of various parts as well as metric, inch, module and pitch threads. The top slides can be operated individually by power for cutting short taper surface also, can be turned automatically through the compound movement combining longitudinal feed with the top slide feed, moreover, the machines may be used for drilling, boring and trepanning. They are characteristics of power, high spindle speed, high rigidity.

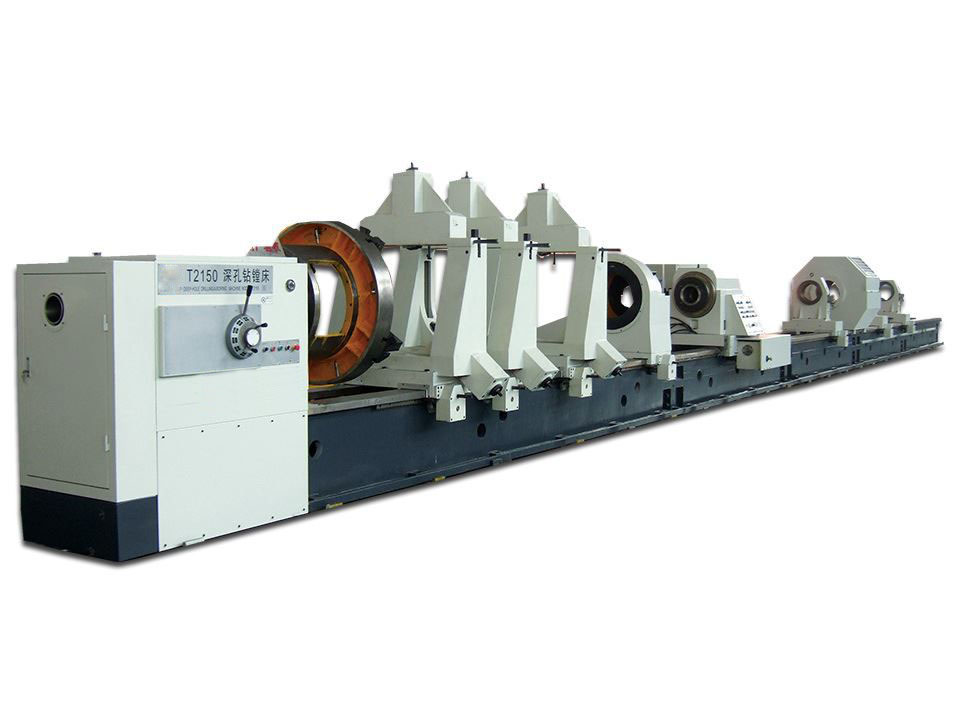

Creating and providing quality T2110G Deep Hole Drilling And Boring Machine, Single Column Vertical Lathe, CNC Heavy Duty Lathe 25Tons Load and value-added services for customers is the value of our company's operation. High quality, high precision, sustainability and high availability are guaranteed. You may be assured that we shall use our best endeavour to execute every order to our customers' satisfaction.

CW-N Series Heavy Duty Lathe Machine 25Tons Load can perform to turn end faces, cylindrical surfaces and internal holes of various parts as well as metric, inch, module and pitch threads. The top slides can be operated individually by power for cutting short taper surface also, can be turned automatically through the compound movement combining longitudinal feed with the top slide feed, moreover, the machines may be used for drilling, boring and trepanning. They are characteristics of power, high spindle speed, high rigidity.

The various ferrous and non ferrous metals parts may be turned through the heavy cutting by carbon alloy tools.

Technology Parameter

Specification | CW61125N | CW61140N | CW61160N | CW61180N | CW61200N | |

Capacity | Swing dia. over bed | Φ1300 | Φ1500 | Φ1700 | Φ1900 | Φ2100 |

Swing dia. over cross slide | Φ900 | Φ1100 | Φ1300 | Φ1500 | Φ1700 | |

Width of bed | 1100mm | |||||

workpiece length | 1000-16000mm | |||||

The max workpiece bearing weight between | 25t | |||||

Spindle | Spindle nose | 1:30 long taper | ||||

Spindle bore diameter | ф100mm | |||||

Taper of spindle bore | Metric No.140 | |||||

Range of spindle speed | 2-200 (manual 4level ) | |||||

Spindle front bearing inner diameter | ф280mm | |||||

Feeds | Longitudinal feeds range | 0.1-12r/min 56Kinds | ||||

Transversal feed range | 0.05-6mm/r 56Kinds | |||||

Metric tread range | 1-120mm 44Kinds | |||||

Inch tread range | 3/8-28TPI 31Kinds | |||||

Modular thread range | 0.5-60mm 45Kinds | |||||

Pitch thread range | 1-56TPI 25Kinds | |||||

Tailstock | Tailstock center taper | 1:7 | ||||

Travel of the tailstock sleeve | 300mm | |||||

Tailstock center sleeve | ф280mm | |||||

Motors | Main motor power | DC55KW | ||||

rapid motor power | 1.5KW | |||||

Cool pump power | 0.125KW | |||||

Standard Accessories

CW61125N | CW61140N | CW61160N | CW61180N / CW61200N | ||

1 | ф1250mm | ф1400mm | ф1600mm | 1 set | |

2 | ф120-470mm | φ400-φ700 | 1set (2-8m) | ||

3 | Follow rest (for more than 2m)50-220 | Follow rest | 1 set | ||

4 | Morse 6# centers | 1 set | |||

5 | center sleeve | 1 set | |||

6 | Tools | 1 set | |||

7 | foundation screws | 1 set | |||

Document with Machine for One Machine Tool

Content | Document | Number | Note |

1 | Operational manuals | 1 | Mechanical and electrical |

2 | Acceptance of certificate | 1 |

|

3 | Packing list | 1 |

The company is a high-tech enterprise integrating scientific research, design, production, sales, maintenance and system integration, mainly engaged in Heavy Duty Horizontal Lathe, Lathe Machine for Turning Steel Roll, Crankshaft, Cylinder, series of machinery. We adhere to the corporate quality concept of casting fine products, and give back to the society with higher quality products, and promote the high quality development of our enterprise. Quality assurance and independent innovation is our company's consistent adherence.

Welcome to send your message to us