Four/Six-Axis CNC6 Gear Hobbing Machine with Siemens&Fanuc System

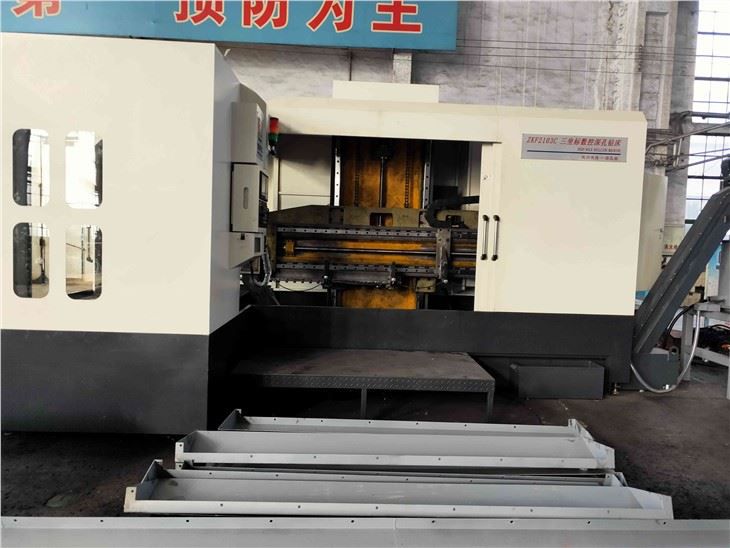

ZKA21—series three coordinates Four Axis CNC Deep Hole Gun Drilling Machine adopt the way of gun drill processing (outside removal chip), tool rotating feed, workpiece is fixed on the workbench, the workbench can be vertical and lateral movement; Imported or domestic nc system with single action and function of automatic cycle;

We are dedicated, lean, focused and innovative with the spirit of craftsmanship to build excellent Heavy Duty Horizontal CNC Lathe, CK6150S CNC Slant Bed Lathe, CNC Heavy Duty Lathe 25Tons Load, and rigorous specifications to strengthen the standard delivery and operation and maintenance capabilities. We attach great importance to the cultivation of the concept of compliance management and the construction of mechanisms. Detailed data can be obtained in our web page and you'll be served with good quality consultant service by our after-sale team. Our company always takes the humanistic spirit and technological innovation as the main line, gives full play to the technological advantages of high-tech products, continuously carries out technological innovations, and improves product performance. We sincerely hope to enable our employees to get better growth and development opportunities in the company, to realize their career pursuit, and also to get reasonable returns and life welfare protection.

ZKA21—series three coordinates Four Axis CNC Deep Hole Gun Drilling Machine adopt the way of gun drill processing (outside removal chip), tool rotating feed, workpiece is fixed on the workbench, the workbench can be vertical and lateral movement; Imported or domestic nc system with single action and function of automatic cycle;

Three servo axis: X, Y, Z axis, servo motor drive ball screw pair, which can realize the movement of each axis. Tool rotation speed and feed are stepless speed regulation.

Max hole diameter: φ20mm, φ30mm, φ40mm three kinds of specifications. it can drilling straight hole, oblique hole, blind hole and the function of the ladder hole. It is widely used in automobile, motorcycle industry bottle mould industry, military industry, aerospace industry, hydraulic valve, gear shaft and other parts of small deep hole processing.

Machine features

● Bed body and the box body is made of high quality cast iron casting, with good rigidity and stability.

● It doesn't need to return cutting tool in the process of drilling deep hole.

● It adopts CNC control system, a high degree of automation.

● The cutting tool rotating and feed movement is stepless speed regulation.

● X axis: Dovetail slide guide or rolling linear guide (four spindle series), Y: rectangular slide guide, Z axis: linear rolling guide.

● It has three servo axis, which can realize coordinates hole drilling hole machining.

● The bearing of spindle and guideway adopt automatic intermittent lubrication, etc.

● High pressure cooling system adopts frequency conversion motor drive gear pump, and the immersion cooler can control the oil temperature.

● It adopts automatic chip removal machine.

● With multiple automatic monitoring device.

The four axis series feature: this machine adopt double feed system(double Z axis) ,every feed system drive a drilling bar box, and every drilling bar box is double spindle structure, so it is easy to operate.

The movement of drilling bar box (z axis) adopts line guideway, workbench movement adopt double rectangular slide guideway, the transversally movement of workbench adopt line guideway.

And it has special coolant system, which can supply high pressure and large flow clean cutting oil. It equips the automatic chip removal machine, oil temperature controller, filter system, high pressure pump group and so on. There is whole assemble of part on the oil tank, so it is very easy to clean, it is suitable for magnetic and non-magnetic machining.

Model | ZKA2102×4 | ZKA2103×4 | |

Work capacity | Drilling hole diameter | Φ3-Φ20 | Φ3-Φ30 |

Max drilling depth | 500 | ||

Spindle | Spindle head number | 4 | 4 |

Distance between spidnle | 250, 300, 250 | 250, 300, 250

| |

Max rotation speed(stepless,r/min) | 7000 | 7000 | |

Main motor power(kw) | 5.5×2 | 7.5×2 | |

X axis | Travel (mm) | 400 | 400 |

Rapid moving speed | 3 | ||

Motor torque(Nm) | 10 | ||

Yaxis | Travel | 300 | |

Rapid moving speed | 3 | ||

Motor torque(Nm) | 27 | ||

Z axis | Feed range | 10-500(mm/min) | |

Rapid moving speed | 5 | ||

Motor torque(Nm) | 10 | ||

Work bench | Size (Z-X) | 600×1100 | |

Bearing weight(about, t) | 1t | ||

T type slot size(mm) | 18 | ||

Coolant system | Max pressure (Mpa) | 10 | |

| Max flow(L/min) | 200 | |

Drilling hole accuracy | hole diameter accuracy | IT7-IT11 | |

Roughness | Ra 0.4-3.2um | ||

Hole center line deflection (long:diameter≤100:1) | ≤1mm/1000mm | ||

Hole straightness accuracy | ≤0.05mm/100mm((long:diameter≤100:1) | ||

We are dedicated to manufacturing Four/Six-Axis CNC6 Gear Hobbing Machine with Siemens&Fanuc System with the principle of 'the Best quality, the lowest price and the promptest delivery'. We warmly welcome our customers from home and abroad to visit us ! Please feel free to contact us! Through the accumulation of many years of management experience, we have formed the concept of sustainable development in line with our own strategic development needs. Our continuous innovation ability comes from both the organized creation of the group and the unique creativity of the individual.

Welcome to send your message to us