Diameter 110 mm Counter Boring Tool Steel Tube Processing Tool

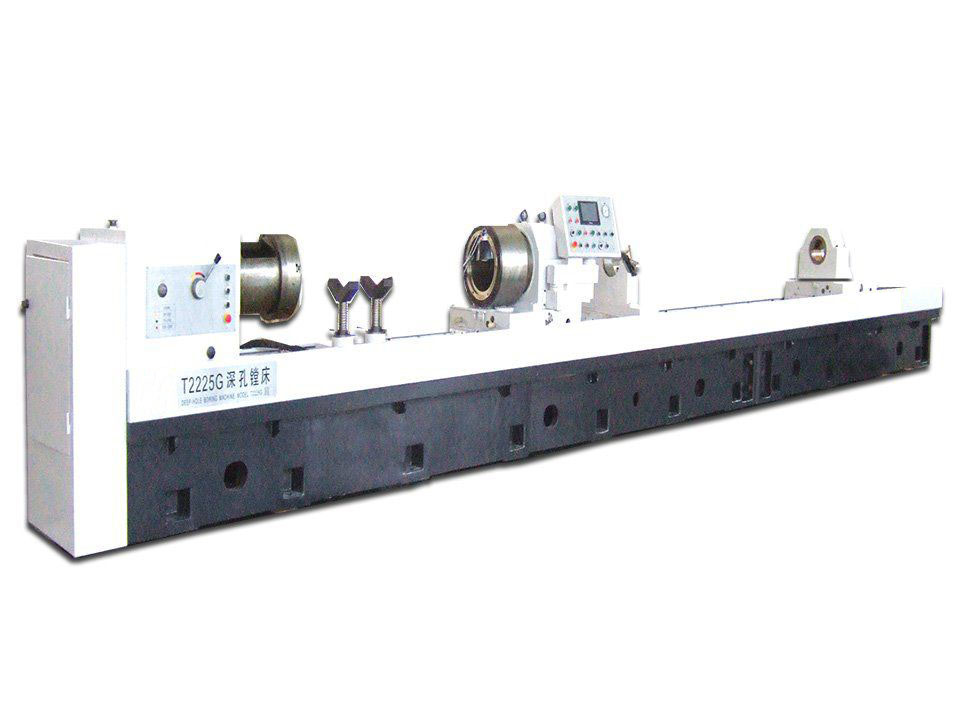

The usage of the machine,the machine is special equipment for machining deep cylindrical hole of workpieces.It suitable for boring the cylindrical workpiece.When boring the hole,the oil is supply from the guide carriage,and take the chips from the cutting area to the equipment of chip conveying on the headstock

We have a complete Heavy Duty Horizontal Lathe Machine, Deep Hole Honing Cutting Tool, Deep Hole Drilling Boring Machine quality data management file, which can satisfy users' retrieval and inquiry of product quality. We have in-house testing facilities where our products are tested on every aspect at different processing stages. We have a consistent team with innovative and pioneering spirit, and we can continuously devote ourselves to the research and development of new products.

The usage of the machine,the machine is special equipment for machining deep cylindrical hole of workpieces.It suitable for boring the cylindrical workpiece.When boring the hole,the oil is supply from the guide carriage,and take the chips from the cutting area to the equipment of chip conveying on the headstock. The drilling method is the internal removal chip(BTA method) when drill.The oil is supply from the guide carriage,and take the chips from the cutting area to the equipment of chip conveying in the back of machine.

The machine is controlled by PLC, the reciprocating movements of guide carriage and feeding carriage are controlled by the servo motor.The drive is made by the racks in the two to ensure long movement feeding transmission accuracy and rigidity requirements. The protection on the two sides of the bed body and the use of the ground oil tank structure improve machine tool environment. The machine can be equipped with two automatic or manual expansion efficient tool,it greatly improves the machining efficiency.

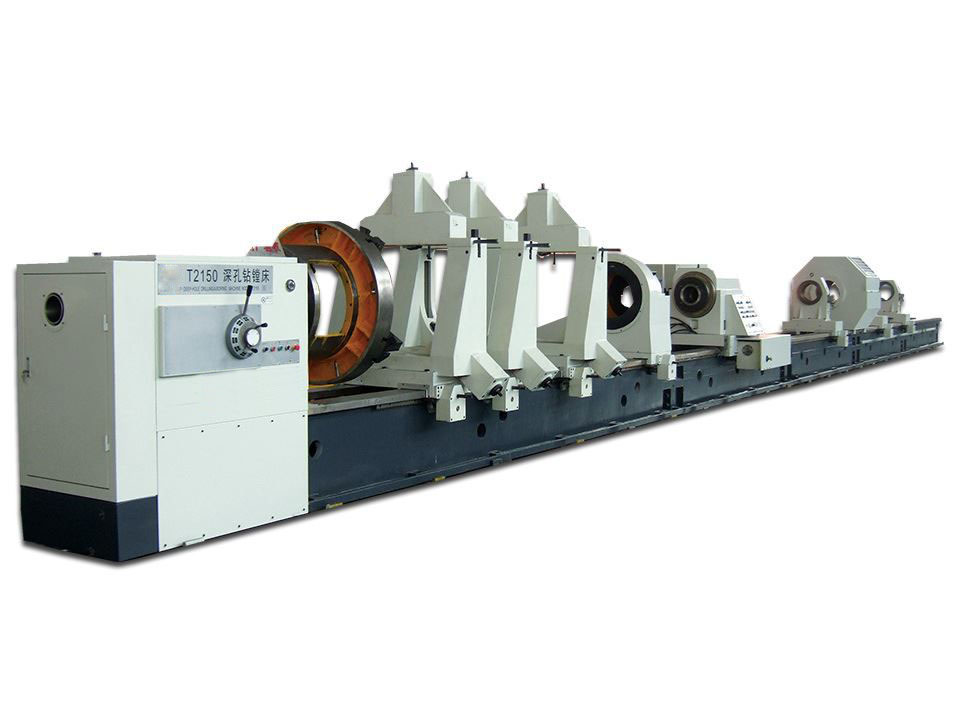

Item | T2150 | T2150Z |

the range of drilling diameter | φ40-φ100mm | φ40-φ120mm |

the range of boring diameter | φ50-φ500mm | φ250-φ500mm if need,can reach φ630mm |

the range of boring depth | 2000~12000mm | 2000~16000mm |

workpiece clamped dia. Range | φ300~φ650mm | φ300~φ1000mm |

the diameter of headstock spindle hole | φ130mm | |

the power of main motor | N=30kW, n=960r/min | N=55Kw DC |

the taper of spindle bore | Metric 140# | |

range and kinds of spindle speed | 3.15~315r/min 21 kinds | 20~200r/min ( four grade stepless) |

range and kinds of drilling box speed | 60~1000r/min 12 kinds | 20~600r/min ( three grade stepless) |

the power of drilling box motor | N=30kW, n=1460r/min | N=45kW, frequency motor |

range of feeding speed | 5~1000mm/min ( stepless) | 5~1000mm/min ( stepless) |

range of rapid speed of carriage | 2000mm/min | 2000mm/min |

the motor of guide carriage | N=7.5Kw YASKAWA AC servo motor | N=11Kw |

feeding motor | N=7.5Kw YASKAWA AC servo motor | N=11Kw YASKAWA AC servo motor |

cool pump motor power | N=11kW n=1440r/min (4 group) | N=22kW n=1440r/min (2 group) |

the rated pressure of cooling system | 2.5MPa | 2.5MPa |

the flow of cooling system | 200, 400, 600, 800L/min; | 0~800L/min; |

the main machine precision | IT7-IT9 | IT7-IT9 |

the max. weight of workpiece | 10t | 20t |

We are an integrated provider of Diameter 110 mm Counter Boring Tool Steel Tube Processing Tool, and related technologies, solutions and services, serving both consumers and companies. Continuing to seek a way out, walking in the forefront of the industry is the development of competitors the correct way. We hope to make our business partners the most trustworthy friends and retain our customers and occupy the market with sincere hearts.

Welcome to send your message to us