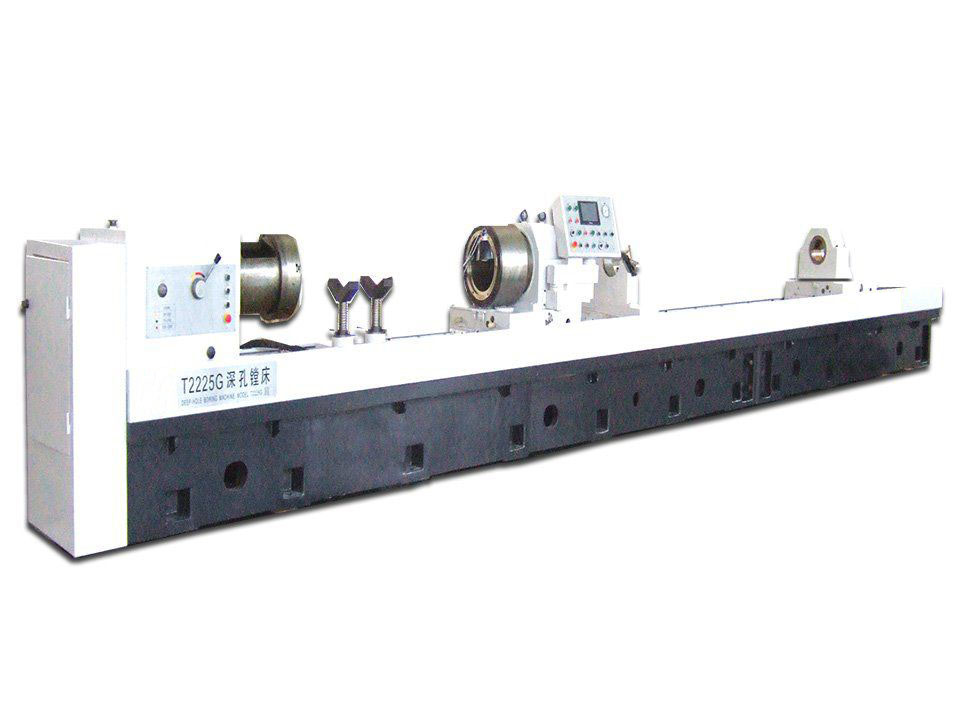

Deep Hole Gundrilling Zk2103A*2 Double Axis Deep Hole Drilling Machine

CNC Deep Hole Gun Drilling Machine is used for processing automobiles, motorcycles, oil pump, nozzle, engineering machinery, mining machinery, military industry and other industries, small and medium-sized deep hole axial workpiece of special equipment.

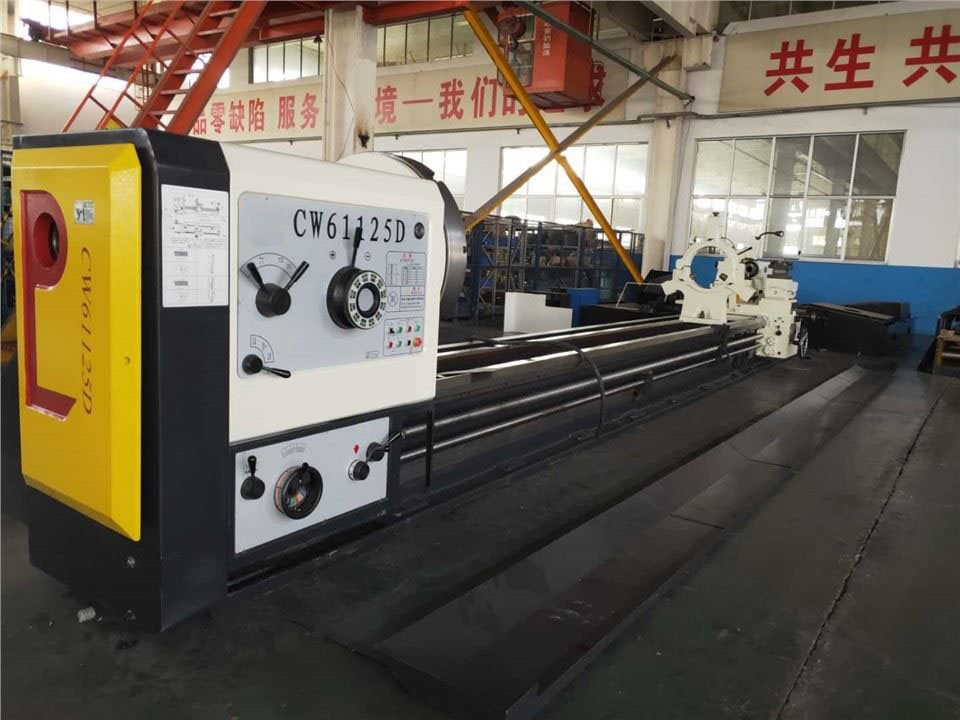

We have a complete and scientific quality management system and can produce HMS25 HMS35 HMS50 Deep Hole Honing Machine, Heavy Duty CNC Lathe Machine, T2110G Deep Hole Drilling And Boring Machine of various specifications according to customer needs. We have ensured that our technology is in line with the international advanced technology, and we will continue to innovate and consolidate our leading position in the industry. We carry out activities such as the collection of rationalized suggestions by all employees to encourage them to contribute to the development of the enterprise.

CNC Deep Hole Gun Drilling Machine is used for processing automobiles, motorcycles, oil pump, nozzle, engineering machinery, mining machinery, military industry and other industries, small and medium-sized deep hole axial workpiece of special equipment.

The machine tool equip the headstock, so the workpiece rotate and cutting tool rotate and feed at the same time, and the accuracy is very high.

Machine features

● Bed body and the box body is made of high quality cast iron casting, with good rigidity and stability.

● It doesn't need to return cutting tool in the process of drilling deep hole.

● It adopts CNC control system, a high degree of automation.

● Feed movement is driven by AC servo motor, and is driven by ball screw pair, and it is stepless speed regulation.

● It adopts sliding guide rail, moving parts bottom with special material, low speed running smoothly, without crawling.

● The drilling bar box is stepless speed regulation.

● The bearing of spindle and guideway adopt automatic intermittent lubrication, etc.

● High pressure cooling system adopts that frequency conversion motor drive gear pump, and the immersion cooler can control the oil temperature.

● It adopts automatic chip removal machine.

● It adopts all closed protective cover, and it is convenient to observe and good appearance.

● With multiple automatic monitoring device.

Optional machining method

A. Standard configuration: Workpiece rotate, cutting tool rotate and feed with gun drilling method.

B. Optional method, the workpiece fixed, the cutting tool rotating and feed with gun drilling method.

Standard configuration

Standard KND or GSK980T numerical control system, headstock, flat screen filter, hand pulse control box, drill pipe support, automatic chip removal machine, all protective cover, centralized lubricating oil station, cooling system, warning lights, adjusting tools, working light, tool pad iron, oil temperature controller, hydraulic system, etc.

Optional configuration

Gun drill tools, auxiliary equipment, cutting oil, knife grinder, grinding device, jilt oil machine, drum filter machine, magnetic chip removal machine, electric box air conditioner, Siemens numerical control system, FANUC CNC system, hydraulic tailstock, clamp.

About ZK-A series single coordinates machine ,the workpiece outer diameter requirement.

ZK2102A series outer dimeter requirement | ||||

Item | The two taper plate against workpiece size (workpiece clamp position size) | Workpiece max outer position size (if the workpiece is ladder shaft, the max workpiece outer diameter dimension) | Spindle center distance | The workpiece diameter for the workpiece support frame position outer diameter dimension(it is used only for preposition) |

Double axis | Φ85mm | Φ170mm | 180mm | Φ100mm |

That is means that if the workpiece is ladder shaft, the workpiece outer diameter dimension is as above list, but two end workpiece outer diameter dimension is not more thanΦ85mm.

The workpiece support frame is used for prepositon of workpiece, when the workpiece is against,the support frame will separate the workpiece, this postion workpiece outer diameter is not more than 100mm.

And if your shaf is straight shaft,max workpiece outer diameter is not more than Φ85mm regardless single, double or four axis machine.

ZK21 A standard parameter | |||

Technology specification | ZK2102Ax2 | ZK2103Ax2 | |

Spindle head number | 2 | 2 | |

distance between spindles mm | 120 | 180 | 180 |

drilling hole diameter range mm | 3-20 | 8-30 | |

max drilling depth mm | 440/950/1450/1950 | 440/950/1450/1950 | |

Drilling bar box spindle rotate speed(stepless) r/min | 800-7000 | 600-6000 | |

Drilling bar box spindle driver motor power | 4kW×2 | 5.5kW | |

Headstock spindle speed(fixed value) | 600 | 600 r/min | |

Headstock spindle motor power | 3 kW | 2.2 kW | |

Cutting tool feed speed range (stepless) mm/min | 5-500 | 5-500 | |

Cutting tool Feed carriage rapid moving speed m/min | 3 | 3 | |

Cutting tool Feed motor torque Nm | 7.7 | 10 | |

Coolant system pressure range MPa | 1-10 | 1-10 | |

Coolant system flow range L/min | 6-100 | 6-150 | |

Machine tool total power (about) | 24 kW | 28 kW | |

Overall dimension (L×W×H) | 4050/5050×4050×2050 | 4050/5050×4050×2050 | |

Total weight (about) | 6t/7t | 6t/7t | |

The accuracy of drilling hole

Accuracy of drilling hole: IT7-IT10 (good condition IT7-IT8; general IT9-IT10) ;

Roughness: Ra 0.4-3.2μm

Deviate of center axis:

A: 0.25mm/500mm (workpiece roate, length :diameter 100: 1, uniform material, suitable feed speed)

B: 0.5mm/1000mm (workpiece roate, length :diameter 100: 1, uniform material, suitable feed speed)

C: 0.5mm/500mm (workpiece not rotate, length :diameter 100: 1, uniform material, suitable feed speed)

D: 1mm/1000mm (workpiece not rotate, length :diameter 100: 1, uniform material, suitable feed speed)

Cutting tool life

Continuous cutting length 12-20m(not include special material)

And cutting tool can use 50times by The cutting tool resharpening , so the total length of cuttting can be more than 600m, good condition is more longer.

We provide our employees with a broad space for development, and we hope that all kinds of talents who are willing to devote themselves to Deep Hole Gundrilling Zk2103A*2 Double Axis Deep Hole Drilling Machine industry will join our team. We keep learning beyond ourselves, keep sharing organizational empowerment, and keep solving customer pain points. We conscientiously implement the idea of ecological civilization and insist on putting energy saving and emission reduction in a prominent strategic position of the enterprise.

Welcome to send your message to us