Deep Hole Gundrill Cutting Tool

The gun drilling is a method of outside chip removal, the cutting oil will enter the cutting tool inner and cutting area from the end of spindle's joint,and the cutting oil will bring chip out through the cutting tool v type slot and workpiece inner hole. The cutting tool guide is by means of guide sleeve before entering the workpiece, and it will depend on self guide function to finish the drilling processing after entering the workpiece.

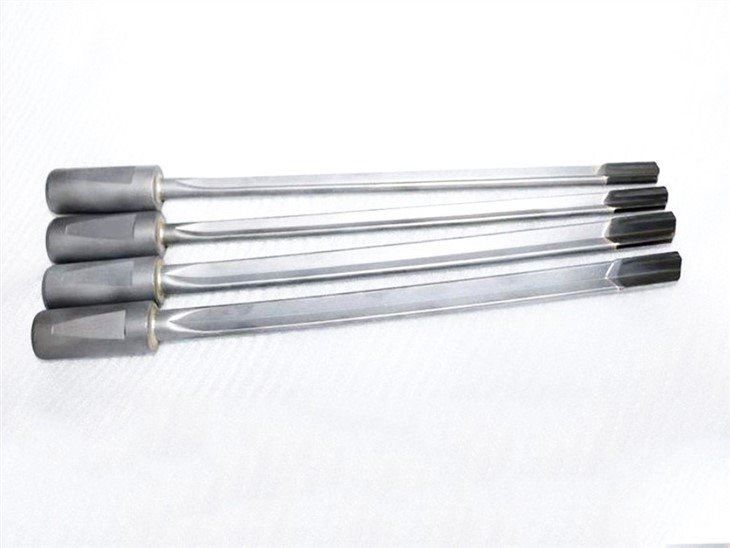

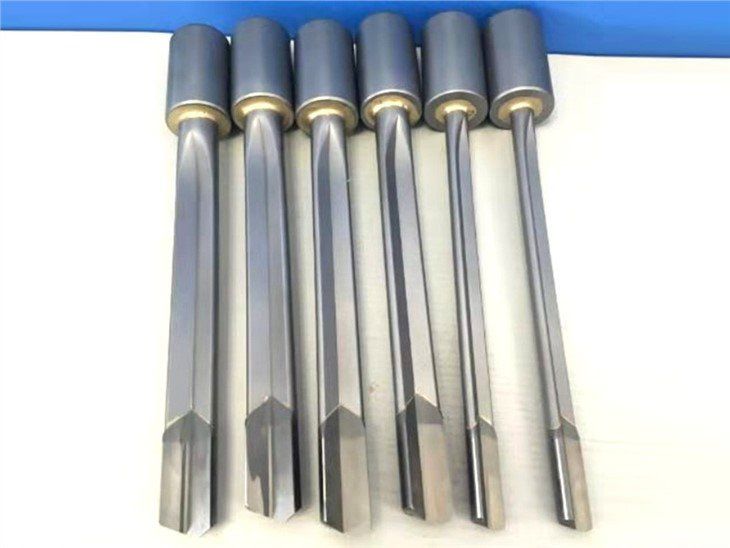

Deep hole gundrill drill head

we supply single fluted gun drill head and total carbide gundril drill head and with insert and pad.

Gun drilling method introduction

The gun drilling is a method of outside chip removal, the cutting oil will enter the cutting tool inner and cutting area from the end of spindle's joint,and the cutting oil will bring chip out through the cutting tool v type slot and workpiece inner hole. The cutting tool guide is by means of guide sleeve before entering the workpiece, and it will depend on self guide function to finish the drilling processing after entering the workpiece. It is suitable to drilling hole≤Φ40mm.

The Deep Hole Processing Characteristics

1) It has very high effiency, which compared with twist drill.In the general case, the hole depth and diameter ratio is≤200: 1. And it can complete drilling process by only one feed,and it doesn't need to return cutting tool. So gun drilling method can obtain excellent dimensional accuracy, straightness, surface roughness, and it can drill straight hole, oblique hole, cross hole, blind hole, etc. At the same time, all the process need high requirement about machine, cutting tool, cutting oil and relative equipment,so good quality and good company is important.

2) The deep hole processing is done in a closed state, so the cutting tool can not be directly observed, so you need more experience and our enginneer help to teach and know the process, you can do only by listening and looking at the chip, observing the machine load and cutting fluid pressure changes, vibration situation, etc. So as to judge the cutting process whether it is normal.

3) Cutting heat is not easy to send out. In general, 80% of cutting heat will be bring away by chip ,but gun drilling method is only 40%. So it must take effective way of forced cooling.

4)Due to the drilling hole is too deep, the chip is not easy to eject, if the chip is too long, it is easy to jam, so you need to control the length of chip.

5)Due to limit of deep hole, the cutting tool is thin and long, it is easy to produce the vibration, it is key design to support and guide the cutting tool, so you need to choose the experience company.

6)The deep hole drilling cutting tool guide function, we design the special Guide block to guide and support the cutting tool.

7)The cutting oil is key to drilling hole, good cutting oil can protect the cutting tool and guide block, and can increase cutting tool life , accuracy, so you need choose special deep hole cutting oil.

The Deep Hole Processing Main Application Fields

At present, it is widely used in mould, automobile, boiler, coal, nuclear power, engineering machine, oil pump, hydraulic pressure, nozzle, war industry (guns), aerospace, medical equipment, tube plate, textile machinery, paper machine,iron and steel (roll), feed machinery, crankshaft, etc.

Welcome to send your message to us