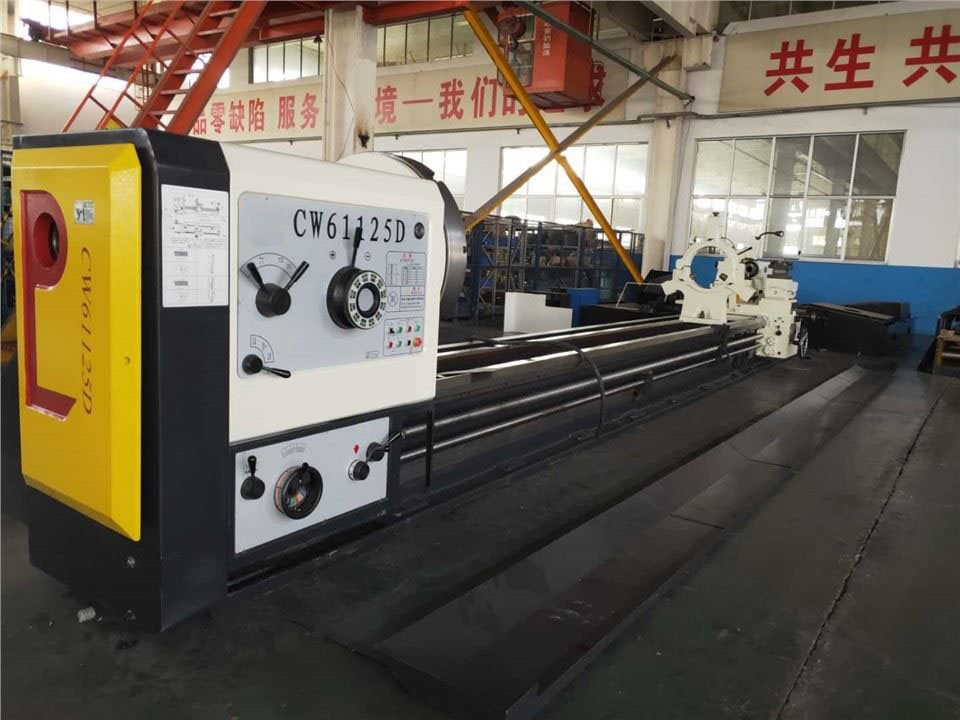

Ck5225 Large Heavy Duty Double Column Turning Vertical Lathe Machine

The workbench and workbench base adopts the whole casting structure with high strength and low stress casting, so it has enough stiffness, strength and thermal stability. And the casting part willl be by second time aging treatment, so as to eliminate stress and ensure the precision of the machine tool for the long-term stability and stability.

We have always taken it as our responsibility to provide customers with quality Oil Cylinder Special CNC Lathe, Casting Bed Honing Machine, CNC Heavy Duty Lathe Machine and good services, and have received many awards from the community. Our company has always implemented a strict quality assurance system, with exquisite production level, advanced management concept, pre-sale, sale and after-sale are quite satisfied with our customers. We will continue to expand our business scope, enhance product advantages and brand reputation, attract new customers, and strive to create greater value for customers and society. We welcome old and new customers to hold hands together for exploring and developing; For more information, be sure to feel free to contact us. We have several sets of perfect equipment and facilities to provide a complete range of products with guaranteed quality and high cost performance.

1.The workbench adopts constant current hydrostatic guideway, which has high working accuracy and strong bearing capacity.

2.The spindle adopts short spindle structure, spindle centering bearing uses double row roller bearings with high accuracy.

3.The main movement adopts AC servo motor or DC motor drive, stepless speed within two level.

4. Tool post uses high rigid rectangular ram with single knief holder structure.

5.Workbench adopts manual four jaw chuck.

6. Machine tool can choose cooling device, automatic chip removal machine, protective device, as optional parts, etc

7. The common tool post is controlled as PLC with LCD screen display, manual pulse tool control the movement of cutting tool.

8. CNC machine can choose domestic or imported numerical control system, also can equip with graing ruler.

9.The tool post can be equipped with milling head or grinding head for multi-usage.

10.The beam guide rail is treated by quenching and grinding processing.

Item | Model | C5240*H*40 | C5250*H*40 | C5263*H*40 |

Max turning diameter | mm | 4000 | 5000 | 6300 |

Max workpiece height | mm | 2000/2500/3150 | 2000/2500/3150 | 2000/3150/3500 |

Workbench diameter | mm | 3500 | 4000 | 4500 |

Max workpiece weight | Tons | 40/50 | ||

Workbench rpm level | Two stepless speed | Two stepless speed | Two stepless speed | |

Workbench rpm range | r/min | I档0.4-13.3/ | I档0.4-13.3/ | I档0.4-13.3/ |

tool post feed speed | mm/min | 4000 | 4000 | 4000 |

tool post feed speed range | mm/min | 0.5~1000 | 0.5~1000 | 0.5-1000 |

Ram cross face | mm | 240*240 | 240*240 | 240*240 |

main motor power | kW | 75 | ||

machine tool weight | t | 95/97/100 | 100/102/105 | 105/113/120 |

Our company has always been adhering to the advanced concept of 'Brand is Competitiveness' and the service tenet is 'Quality First, Brand First, Your Satisfaction, My Wish'. In the fierce market competition, we will continue to innovate and create brilliance together with all walks of life and users, and make contributions to the Ck5225 Large Heavy Duty Double Column Turning Vertical Lathe Machine industry. We implement the new development concept and strive to build a world class enterprise with global competitiveness. We believe that integrity wins the world, quality achieves Mingheng, and win-win cooperation to create a better future!

Welcome to send your message to us