CAK6140/6150/6166/6180 Horizontal Flat Bed metal CNC turning Lathe Machine

CKD6163D Series CNC Lathe Machine 3Tons Load is CNC lathe used for machining various kinds of steel parts. It is specially suitable for mass production of machining inside and outside cylinder surface, end surface, metric and inch thread etc. It can also perform the function of drilling and boring hole.

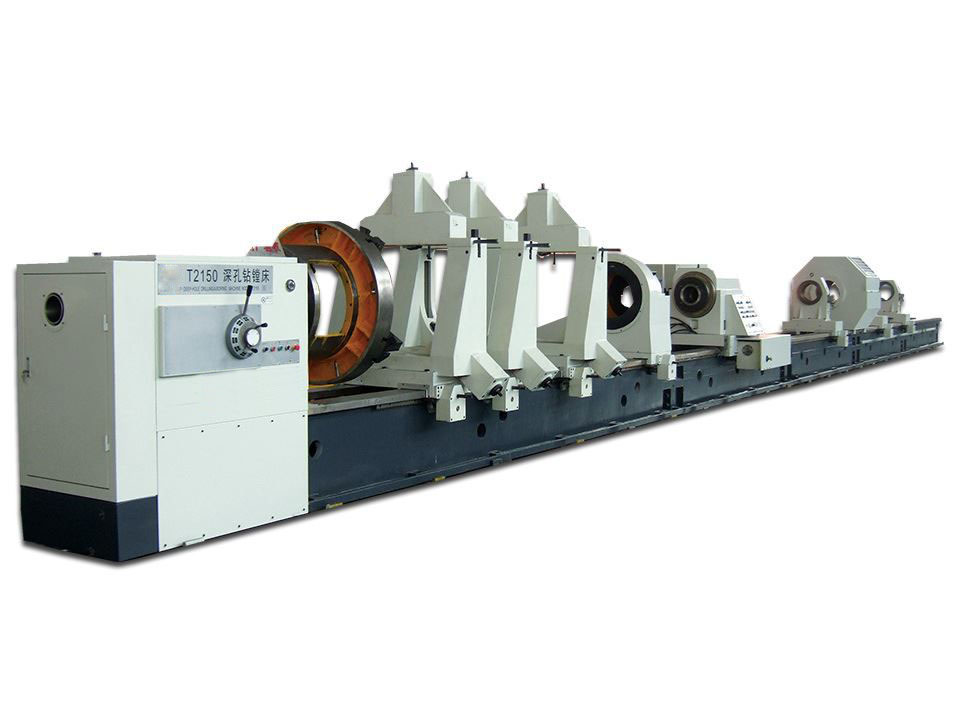

Through our unremitting efforts, our new technological achievements continue to emerge, and the development of new CW-N Series Heavy Duty Lathe Machine 25Tons Load, T2180 Deep Hole Drilling And Boring Machine, Heavy Duty Lathe Machine continues to make new progress. With your support, we will grow much better. Scientific management and superior scientific research conditions have created a high-tech, high-quality and innovative young and middle-aged scientific and technological team.

CKD6163D Series CNC Lathe Machine 3Tons Load is CNC lathe used for machining various kinds of steel parts. It is specially suitable for mass production of machining inside and outside cylinder surface, end surface, metric and inch thread etc. It can also perform the function of drilling and boring hole.

Main features

1) Main spindle speed is infinite of varies speed so as to realize change speed without stop spindle. Speed range is wide and suitable for rough and finish turning.

2) The bed is made of high strength resin cast iron, the guide-way is hardened by ultra-high frequency quench and precision ground with properties of good precision-keeping and strong loading capacity.

3) It is adopted high power low noise servo motor, so the machine has high positioning accuracy, good stability and high reliability.

4) The machine is equipped four-position automatic rotary turret with intermittent automatic lubrication which the user can adjust according to the condition. It fully guarantee the rail surface lubrication and improve the accuracy of machine effectively.

5) The machine has double door and semi protective structure, so it has beautiful shape and easy to operate.

Specification

|

Machine Tool Parameter |

|

|

The Max. Swing Diameter Over Bed |

φ 630mm |

| The Max Swing Diameter Over Cross Slide | φ 350mm |

|

The Max Distance Between Centers |

2000 mm |

| Max Workpiece Turning Length | 1850 mm |

| Bed width | 600mm |

| Max Bearing Weight Between Two Center | 3t |

| Guide Heatment Hardness | Hrc50 |

| Spindle Parameter | |

| Spindle Center Height | 320mm |

|

The Speed of Spindle Manual Four Level And, Stepless Speed in Four Levels |

17-1000 R/min (Ⅰ: 17-100r/min, Ⅱ: 35-225r/min, Ⅲ: 74-450r/min Ⅳ: 180-1000r/min |

| The Diameter of Spindle | φ100mm |

| The Taper of Spindle Front Hole | metric 120 |

| The Typer of Spindle Nose | c 11 |

|

The Power of Main Motor(china Domestic Servo Motor) |

15kw |

| Feed | |

| X Axis Rapid Movement Speed | 4000mm/min |

| Z Axis Rapid Movement Speed | 6000mm/min |

| X Axis Travel | 450mm |

| X-axis Feed Motor | 11n.m(siemens) |

| Z-axis Feed Motor. | 22n.m(siemens) |

| Smallest Unit of Tool Post | X Axis 0.001 Z Axis 0.001 |

| Tool post | |

| Tool Post | Vertical 4position Tool Post |

| Model | ak21240x4 |

| The Section Of Tool | 32×32mm |

| Tool Post Repeat Position Accuracy | 0.01mm |

| Tail stock | |

|

The Diameter of Tailstock Sleeve |

φ120mm |

| The Max.travel of Tailstock Spindl | 200mm |

|

The Taper of Tailstock Sleeve |

Morse 6# |

|

Cooling and Lubrication |

|

| Cooling Pump Model | Jcb-45 |

| Lubrication Form | intermittent Automatic Lubrication |

| Lubrication Station Volume | 1.5l |

| Other | |

| Form of Cover Protection | Double Sliding Door, Semi-closed Protection |

|

Configration |

|

| Workpiece Loads Weight |

3tons, 600mm Bed Width |

|

With Simenes 808 |

|

| Standard Configuration | CKD6163D |

| with Manual Three-jaw Chuck φ380mm | 1set |

| Steady Rest 50-300mm | 1set |

| Follow Rest50-150mm | 1set |

| Center Sleeve | 1set |

| Morse 6# Center | 2set |

| Oil Gun | 1pcs |

| Tools | 1set |

| Foundation Screws | 1set |

|

Commodity and Specification |

|

Change to simens828 system |

|

Face plate |

|

Drive plate |

|

Chip remove machine |

|

Hydraulic chuck, taiwan 15” middle solid |

|

Hydraulic chuck, taiwan 15” middle hollow |

|

Hydaulic tailstock, rotating center |

|

Hydaulic tailstock, no rotating center |

Document with Machine for One Machine Tool

|

Content |

Document |

Number |

Note |

|

1 |

Operational manuals |

1 |

Mechanical and electrical |

|

2 |

Acceptance of certificate |

1 |

|

|

3 |

Packing list |

1 |

|

We produce high-quality CAK6140/6150/6166/6180 Horizontal Flat Bed metal CNC turning Lathe Machine with advanced equipment and scientific management, win the favor of customers with high-quality products and good service, and win our glory with the favor of customers. Through cultural training, incentive mechanism and work experience, we create an atmosphere that stimulates people's progress and growth, and inspires employees' career, responsibility and mission. We strengthen the training and education of our employees, and flexibly apply the compensation and benefits designed for different positions and functions, so that our employees can get a sense of security, belonging and achievement from the company.

Welcome to send your message to us