6mm 2 Flute Carbide Metal Grinding Deep Hole Twist Drill Bits Set for Steel 50HRC

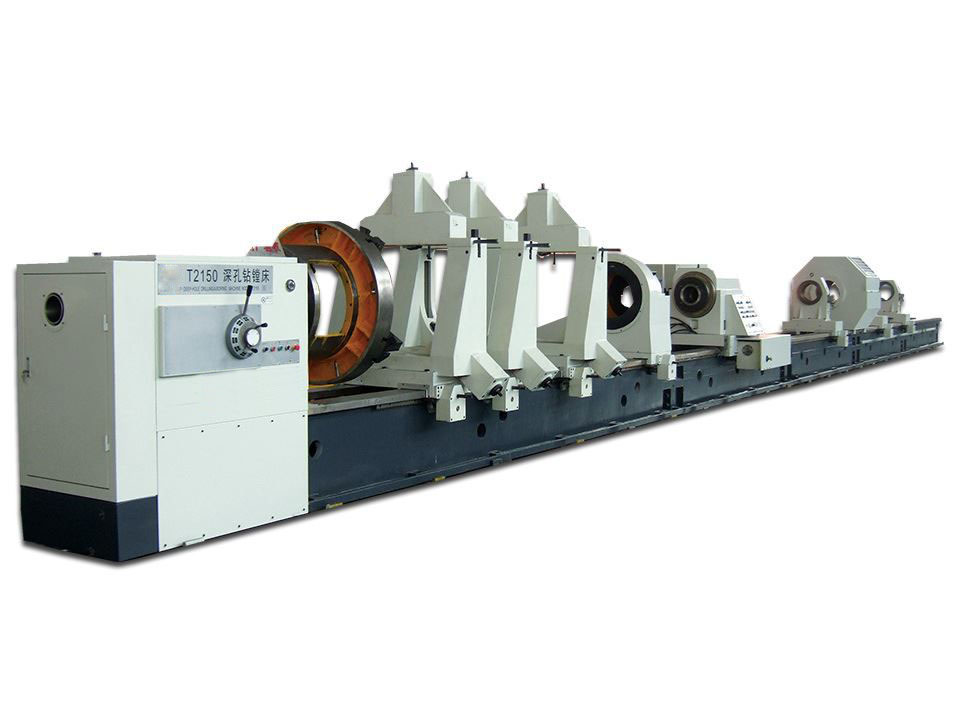

The usage of the machine,the machine is special equipment for machining deep cylindrical hole of workpieces.It suitable for boring the cylindrical workpiece.When boring the hole,the oil is supply from the guide carriage,and take the chips from the cutting area to the equipment of chip conveying on the headstock

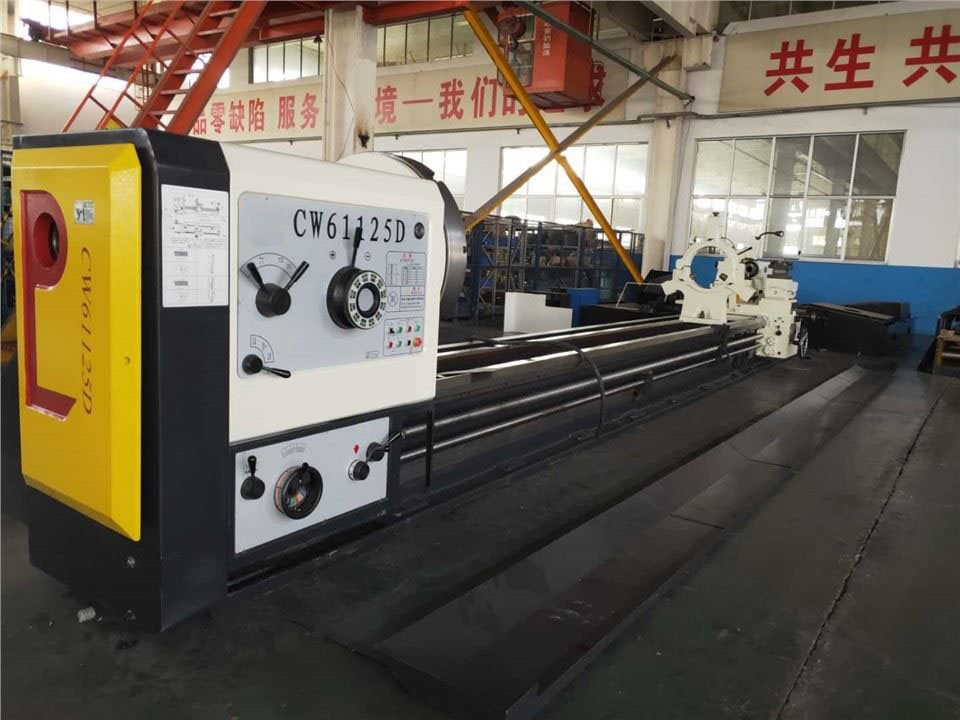

It is the most important responsibility of our company to provide safe, stable and reliable technology and Heavy Duty Horizontal CNC Lathe 40Tons Load, Single Coordination CNC Gun Drilling Machine, Deep Hole Drilling and Boring Machine to our customers. We believe that the improvement of the system and the establishment of the mechanism are particularly important in the process of staff ideological training and quality improvement. We effectively utilize the company's diverse capital and related resources to actively expand business scope. Our company takes integrity as the core, and puts integrity throughout every link of operation and management, customer service, communication and cooperation, and win-win development.

The usage of the machine,the machine is special equipment for machining deep cylindrical hole of workpieces.It suitable for boring the cylindrical workpiece.When boring the hole,the oil is supply from the guide carriage,and take the chips from the cutting area to the equipment of chip conveying on the headstock. The drilling method is the internal removal chip(BTA method) when drill.The oil is supply from the guide carriage,and take the chips from the cutting area to the equipment of chip conveying in the back of machine.

The machine is controlled by PLC, the reciprocating movements of guide carriage and feeding carriage are controlled by the servo motor.The drive is made by the racks in the two to ensure long movement feeding transmission accuracy and rigidity requirements. The protection on the two sides of the bed body and the use of the ground oil tank structure improve machine tool environment. The machine can be equipped with two automatic or manual expansion efficient tool,it greatly improves the machining efficiency.

Item | T2150 | T2150Z |

the range of drilling diameter | φ40-φ100mm | φ40-φ120mm |

the range of boring diameter | φ50-φ500mm | φ250-φ500mm if need,can reach φ630mm |

the range of boring depth | 2000~12000mm | 2000~16000mm |

workpiece clamped dia. Range | φ300~φ650mm | φ300~φ1000mm |

the diameter of headstock spindle hole | φ130mm | |

the power of main motor | N=30kW, n=960r/min | N=55Kw DC |

the taper of spindle bore | Metric 140# | |

range and kinds of spindle speed | 3.15~315r/min 21 kinds | 20~200r/min ( four grade stepless) |

range and kinds of drilling box speed | 60~1000r/min 12 kinds | 20~600r/min ( three grade stepless) |

the power of drilling box motor | N=30kW, n=1460r/min | N=45kW, frequency motor |

range of feeding speed | 5~1000mm/min ( stepless) | 5~1000mm/min ( stepless) |

range of rapid speed of carriage | 2000mm/min | 2000mm/min |

the motor of guide carriage | N=7.5Kw YASKAWA AC servo motor | N=11Kw |

feeding motor | N=7.5Kw YASKAWA AC servo motor | N=11Kw YASKAWA AC servo motor |

cool pump motor power | N=11kW n=1440r/min (4 group) | N=22kW n=1440r/min (2 group) |

the rated pressure of cooling system | 2.5MPa | 2.5MPa |

the flow of cooling system | 200, 400, 600, 800L/min; | 0~800L/min; |

the main machine precision | IT7-IT9 | IT7-IT9 |

the max. weight of workpiece | 10t | 20t |

We offer wonderful energy in high-quality and improvement, merchandising, product sales and marketing and advertising and procedure for 6mm 2 Flute Carbide Metal Grinding Deep Hole Twist Drill Bits Set for Steel 50HRC. One mind and one strength is the ideological premise of our company's reform and development, and we take entrepreneurship and innovation as the source of power. In every link of the production process, we have formulated strict standard operating procedures, and the pursuit of excellence has been unanimously recognized by the industry and customers.

Welcome to send your message to us